GAS TURBINE BLADE’S COATINGS LIFE TIME AND AVERAGE TEMPERATURE ANALYSIS AND PREDICTION

Problem. Resource MCrAlY type metal coating determines the durability of life time of gas turbine blades. Since the resource coatings should reach tens and hundreds of thousands of hours of full-scale experimental study was conducted to determine the number of coverage options. Calculation methods let you define resource coating in different types of work conditions of the blade.

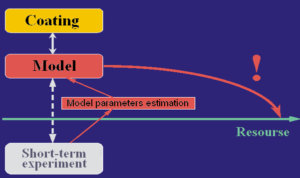

Proposition solutions. With the help of the developed model was analyzed resource and medium temperature protective coatings gas turbine engine blades. It uses the computational-experimental approach is based on a model describing the basic physical and chemical processes that determine coating resource through an identity the model parameters for experimental studies (Figure 1).

Fig. 1. The idea of solving the problem by definition coating life time

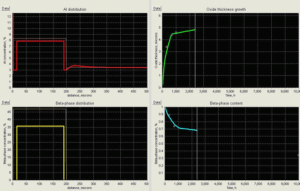

This approach and the model are realized in the program COLTAN (Coating Life Time Analysis), allows the analysis of oxidation and diffusion processes in the coating by direct comparison with experiment. Figure 2 shows fragments COLTAN interface.

Fig. 2. Interim point calculation program concentration profiles of various aluminum phases in the program COLTAN

A program product is capable of a brief natural experiments to determine the long-term life time resourse of the gas turbine engine blade.

The work was done for:

- Implementation of the International project NATO Science for Peace 972631 – Life time modelling for MCrAlY coatings for industrial gas turbine blades (1999-2003 гг.).

- Institute of Chemical Technology (Germany) for the study of coatings used in the firm “EdF” (Electricity de France) (France) – Life time prediction by inverse problem solution for an MCrAlY coating used by Electricite de France (2001 – 2002 гг.).

- Companie SIEMENS AG, Power Generation (Germany)- MCrAlY coating life time analysis with COLTAN software and SICOAT data (2003-2004 гг.).

Publications:

- Leonid Borisovich Getsov, P. G. Krukovski, N .V. Mozaiskaja, Aleksander I. Rybnikov, K. A. Tadlja A NEW METHOD FOR DETERMINING THE REMAINING LIFETIME OF COATED GAS-TURBINE BLADES // Materials and technology 2011, V.45, N 1, pp. 21–26.

- Krukovsky P., Kolarik V., Tadlya K., Rybnikov A., Kryukov I., Juez–Lorenzo M. Theoretical and experimental approach for long term modelling of oxidation and diffusion processes in MCrAly coatings – of EFC Workshop “Lifetime Modelling of High Corrosion Processes”, 2001, №34, p. 231-245

- Krukovsky P., Tadlya K., Rybnikov A., Kryukov I., Mogaiskaya N., Kolarik V., Juez-Lorenzo M. Combined experimental and theoretical approach for long time high temperature oxidation and diffusion processes in MCrAlY coatings investigation. – Proceedings of the VIII seminar “Diffusion and thermodynamics of materials”. Brno, 2002 pp 176-179.