PREDICTION OF THERMAL DEFORMATION OF DETAILS IN TURNING USING VARIOUS COOLING METHODS

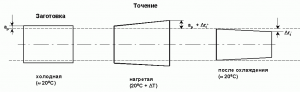

The modern engineering is accompanied by the development of new construction, heat-resistant and wear-resistant steels and alloys with high strength properties. Mechanical processing of such materials is accompanied by the appearance of thermal deformations which lead to distortion of detail dimensions after the turning (figure 1).

Fig.1. The appearance of sized temperature error after turning detail Drt

Development of optimal schemes computational and experimental approach to the prediction of temperature fields (fig. 2) and deformations in turning of details using various cooling methods can control turning precision by selecting the cooling method and (or) the correction of the tool movement.

The use of the proposed model and methods to ensure its adequacy is the basis not only for predicting the thermal deformation details to ensure the specified accuracy in turning and the basis for control and development of the thermal deformation laws movement correction tool in turning.

Fig. 2. – Thermal detail field in the cutting process

For the first time developed the physical, mathematical and computer models of calculation of temperature deformations in multipass turning of details with different types of cooling.

Publications:

- SukayloA., Kaldos A., Krukovsky P., Lierath F., Pieper H.J., Emmer T., Kundrak J., Bana V. Development and verification of a computer model for thermal distortions in hard turning // Proc. of the international conference on advances in materials and processing technologies (AMPT), Dublin, 2003, p.333-336.

- Sukaylo, Krukovsky P., Kundrak J., Emmer T. Numerical modeling of thermal strains in turning with use of different cooling methods // Resanie i instrument. 62´ 2002. pp. 119-126.