LABORATORY OF THERMOPHYSICAL FUNDAMENTALS OF DISCRETE PULSE ENERGY INPUT

Contacts

Bulakhovskii St. 2, Kyiv, Ukraine, 03164

tel.: (044) 424 13 06; (044) 424 14 96

Fax.: (044) 424 13 06

e-mail: ittf_tds@ukr.net

HISTORY OF LABORATORY

The Laboratory of Thermophysical Fundamentals of Discrete Pulse Energy Input was created in 1978 as part of the Department of Spray-Transfer Heat and Mass Exchange Devices, later renamed the Department of Heat and Mass Exchange in Dispersed Systems (TDS) under the leadership of Academician of the National Academy of Sciences of Ukraine, Honored Worker of Science and Technology, and three times the winner of the State Prize of Ukraine, Anatoliy Andriyovych Dolinskyi. Since 2020, the head of the department is Dr. Tech. Sciences, Prof. Oleksandr Mykolayovych Obodovych.

Until 2015, the Laboratory was managed by Yulia Oleksandrivna Shurchkova, Doctor of Technical Sciences, Professor, Honored Scientist and Technician, and twice State Prize winner; since April 2015 – leading researcher, Candidate of Technical Sciences (Ph.D.) Alina Vasylivna Konyk. Since January 2020, the Laboratory has been managed by a leading researcher, Candidate of Technical Sciences (Ph.D.) Bogdan Yaroslavovych Tselen.

The main direction of the Laboratory’s activity is theoretical and experimental research of heat and mass transfer and hydrodynamic processes in multicomponent liquid media, which formed the basis for creating a new scientific direction of discrete pulse energy input in heterogeneous environments (DPEI), which was originated by the Laboratory team.

On the basis of theoretical and experimental research, Laboratory employees have developed more than 20 fundamentally new technologies and types of equipment for the medical, food, pharmaceutical, microbiological, cable industry, agriculture, which have been implemented at more than 600 industrial facilities and presented at numerous exhibitions, awarded with gold, silver and bronze medals of the USSR Independence Square, the Golden Medal of the Leipzig Fair, twice awarded the State Prize of Ukraine.

Employees of the Laboratory defended 3 theses for the Doctor of Technical Sciences degree and 9 theses for the Candidate of Technical Sciences degree (Ph.D.). The Laboratory employs 13 employees, of whom 8 are Candidates of Technical Sciences (Ph.D.) and 2 are Doctors of Technical Sciences.

MAIN DIRECTIONS OF THE LABORATORY’S ACTIVITIES

- Development and research of mechanisms of disperse-impulse input of energy in heterogeneous environments based on the processes of adiabatic boiling, high-frequency hydrodynamic oscillations, cavitation.

- Development of technologies and equipment based on mechanisms of disperse-impulse input of energy in heterogeneous environments for various industries.

- Implementation of developed technologies and equipment.

MOST IMPORTANT PROJECTS PERFORMED IN THE LABORATORY 1978 – 2015

Investigation of microscale thermophysical processes in complex heterogeneous systems under the influence of disperse-impulse input of energy in heterogeneous environments mechanisms for the development of new technologies and products (registration number 1.7.1.840. 2012 – 2016 gg.). Leader – Academician of the National Academy of Sciences of Ukraine A. A. Dolinsky, responsible executor – Dr. Sci. Yu.A.Shurchkova.

Development of methods of intensification of processes of hydration, hydrolysis and extraction on the basis of the use of DIVE mechanisms (registration number 1.7.1.852. 2014). Scientific supervisor – academician of the National Academy of Sciences of Ukraine A.A.Dolinsky, responsible executor – Dr.Sc. Yu.A.Shurchkova.

Investigation of heat and mass transfer with discrete impulse input of energy in heterogeneous systems for the purpose of development of nanotechnologies and their realization (registration number 1.7.1.712, 2011). Scientific supervisor – academician of the National Academy of Sciences of Ukraine A.A.Dolinsky, responsible executor – Dr.Sc. Yu.A.Shurchkova.

Investigation of the effects of disperse-impulse input of energy in heterogeneous environments on water treatment in the production of reconstituted foods, medical products, water-alcohol mixtures (registration number 1.7.1.812 2011). Scientific supervisor – Dr. Sci. Yu.A.Shurchkova.

Development, manufacturing and testing of a prototype industrial model for processing water and water-alcohol mixtures (registration number 1.7.1.41. 2009). Scientific supervisor – academician of the National Academy of Sciences of Ukraine A.A.Dolinsky, responsible executor – Dr.Sc. Yu.A.Shurchkova.

Study of thermophysical and hydrodynamic bases of discrete-pulsed input of energy in order to create nanotechnological processes (registration number 1.7.1.618. 2008). Scientific supervisor – academician of the National Academy of Sciences of Ukraine A.A.Dolinsky, responsible executor – Dr.Sc. Yu.A.Shurchkova.

Development, manufacturing and testing of a pilot-industrial model of a device for processing milk with a productivity of 10-20 t/h (registration number 1.7.1.42. 2008). Scientific supervisor – academician of the National Academy of Sciences of Ukraine A.A.Dolinsky, responsible executor – Dr.Sc. Yu.A.Shurchkova.

Research of thermophysical and hydrodynamic methods of influence on water and biological structures of thermolabine liquids and pastes. The work was carried out in accordance with the Resolution of the Presidium of the NAS of Ukraine No. 101 dated April 11, 2007 and the order of the Presidium of the National Academy of Sciences of Ukraine No. 265 dated 19.04.2007. Scientific adviser – academician of the National Academy of Sciences of Ukraine A. A. Dolinsky, responsible executor – Dr.Sc. Yu.A.Shurchkova.

Development of new technologies of dispersing, mixing and processing of liquid disperse media using physical mechanisms of disperse-impulse input of energy in heterogeneous environments (registration number 1.7.1.622. 2005). Scientific supervisor – academician of the National Academy of Sciences of Ukraine A.A.Dolinsky, responsible executor – Dr.Sc. Yu.A.Shurchkova.

Investigation of processes of dispersion, heat treatment and mixing of multicomponent systems and development of technologies for obtaining compositions on soybean basis (registration number 1.7.1.623. 2005). Scientific supervisor – Dr. Sci. Yu.A.Shurchkova.

The thermophysical foundations of the method of discrete-pulse energy input (registration number 1.7.1.587 2002). Scientific supervisor – Dr. Sci. Yu.A.Shurchkova.

Investigation of hydrodynamics and dispersion processes during the flow of multicomponent liquid mixtures in the area of small overheating and the study of the physical and chemical properties of specific phenomena during the influence on thermolab system systems of the DIVE (1999) Scientific supervisor – Dr. Sci. Yu.A.Shurchkova.

Development of scientific principles of discrete impulse input of energy and creation of new technologies of mixing, emulsification and sterilization of liquid disperse systems (registration number 0193/004494, 1993). Scientific supervisor – AA Dolinsky, responsible performer – Yu.A.Shurchkova.

Development of technology and equipment for milk homogenization. The work was carried out in accordance with the Decree of the RS of the RSFSR No. 250 of July 11, 1985; Programs RH 35.10; Decree of the State Planning Committee of the USSR No. 88 of 29.12.1985; By the Decree of the SCNT of the USSR No. 221 dated April 5, 1989, the scientific supervisor – AA Dolinsky, the responsible performer – Yu.A.Shurchkova. The work was awarded to the State Prize of Ukraine in the field of science and technology.

Develop a technology and create a device for emulsifying substitutes of whole milk with a productivity of 12 t / a finished product. Topic RN 39.10.10. 1980 – 1985. The work was carried out in accordance with the Decision of the State Planning Committee of the USSR of May 31, 1982 No. PA – 206 / 41-284 and the Decree of the Council of Ministers of the USSR No. 125 dated March 17, 1983. Scientific supervisor – Yu.A.Shurchkova. The work was awarded the State Prize of the Ukrainian SSR in the field of science and technology.

Development of technology and equipment for the production of sterile emulsions for the medical industry. The work was carried out at the order of the Ministry of Medical Industry of the USSR. 1973 – 1975. Scientific supervisor AA Dolinsky, responsible performer – Yu.A.Shurchkova.

Development of the method of intensification of the liquid extraction process with a fast-acting reaction with the concentration of water-butanol solutions of penicillin. The work was carried out in accordance with the Decree of the SCNT of the USSR No. 23 of January 30, 1968; Theme 0.74.303a, 1968-1973g. Scientific supervisor – AA Dolinsky, responsible performer – Yu.A. Shurchkova.

Research of the physical mechanisms of the energetic influence of the discrete-pulse energy input method on aqueous heterogeneous systems for use in the food industry and energy. – Section 2 of the report on scientific research work on fundamental research under program-target topic 1.7.1.881 “Investigation of energy transformation processes in liquid heterogeneous systems using the method of discrete-pulse energy input” (implementation period 2017 – 2021). The head is Academician of the National Academy of Sciences of Ukraine A.A. Dolinskyi, responsible executors – Ph.D. B.Ya. Tselen, Dr. Sci. I.O. Dubovkina. State registration number 0117U000949.

Conducting research on the physical and chemical properties of heat-accumulating materials – as co-executors of scientific and technical work under the state order “Development of a system of storage and mobile transportation of thermal energy” under the contract with the Ministry of Education and Science of Ukraine No. ДЗ/80-2019. The scientific leader of the project is the head of the laboratory of High Processes and Technologies of Heat Supply, Ph.D. V.G. Demchenko. State registration number 0119U103145.

Scientific and technical work under the State order “Development of a two-chamber apparatus for reagent-free neutralization of acidic condensates of gas combustion products in heating and industrial boilers” under the contract with the Ministry of Education and Science of Ukraine dated October 30, 2015, No. ДЗ/52-2015. The scientific leader of the project is Academician of the National Academy of Sciences of Ukraine A.A. Dolinskyi, responsible executor Ph.D. B.Ya. Tselen. State registration number 0115U005525.

Scientific and technical work under the State order “Development and implementation of the experimental model of apparatus for neutralization of condensate of natural gas combustion products” under the contract with the State Agency for Science, Innovation and Informatization of Ukraine dated October 31, 2013, No. ДЗ/456-2013. The scientific leader of the project is Academician of the National Academy of Sciences of Ukraine A.A. Dolinskyi, responsible executor Dr. Sci. Yu.O. Shurchkova. State registration number 0113U006201.

Theoretical and experimental studies of heat and mass transfer in technological processes using the method of discrete pulse energy input (DPEI). Program-target topic 1.7.1.860, implementation period 2016 – 2019. Leader – Academician of the National Academy of Sciences of Ukraine A. A. Dolinsky, responsible executor – Ph.D. A.V. Konyk, Dr. Sci. G.K. Ivanitsky.

NEW DEVELOPMENTS

TECHNOLOGY AND EQUIPMENT FOR NON-REAGENT NEUTRALIZATION OF CONDENSATE OBTAINED AFTER NATURAL GAS COMBUSTION

The technology and equipment for the non-reagent neutralization of acid condensate of products of natural gas combustion, designed to work in combination with the installation of deep utilization of heat of flue gases (economizer of deep cooling) of gas boilers is developed.

The equipment is in continuous operation and fully automated.

Implementation of the deep utilization of heat of flue gases in a complex with equipment for the reagent neutralization of acidic condensate will reduce the need for using fresh water to boil boilers by replacing it with neutralized condensate, reducing the load on the environment due to the absence of drains.

TECHNOLOGY OF WATER-SPIRIT MIXTURE PRODUCTION

A new technology for the production of water-alcohol mixtures (solutions) has been developed, which includes pre-treatment of water by the influence of high-frequency hydrodynamic oscillations , followed by mixing with alcohol, also in the mode of high-frequency hydrodynamic oscillations. The project carried out experimental research and modeling of the process of hydration of ethanol molecules with water molecules, which allowed to determine the main parameters of the process of obtaining a water-alcohol mixture. The technological scheme and equipment for the implementation of technology are offered. The technology and equipment have undergone an industrial test and are implemented at one of the enterprises of the liqueur industry.

EQUIPMENT FOR MANUFACTURE OF DIFFERENT EXTRACTS FROM VEGETABLE RAW MATERIALS

A pilot-industrial sample of a cavitation reactor of a pulsating type has been developed and created for obtaining various extracts from plant raw materials, the action of which is based on the use of effects of hydraulic impact.

Equipment, during extraction of plant material, allows obtaining maximum yield of target components, and also allows to significantly intensify the processes of dispersion, homogenization and mixing, in comparison with the current used industrial equipment.

This equipment allows to receive extracts from any kind of plant material, opens up possibilities of its wide application in various branches of food, alcoholic beverage, medical industry, cosmetology and agroindustrial complex:

– in the pharm industry in the production of various medical tinctures, dietary supplements;

– in cosmetology – for the production of creams, gels, shampoos based on extracts of plant material;

– in the food industry – for prophylactic natural concentrates-additives;

– in the liquor industry – for the grassy tinctures-bases or natural flavors that can be used in the manufacture of high-quality vodka or cognacs.

For the chemical industry, we have already worked out the regime parameters for conducting the process of extracting humic substances from low-grade peat, depending on the required productivity with the possibility of further application in the agroindustrial complex.

THERMOVACUUM TECHNOLOGY FOR LIQUIDS PROCESSING

The technology is based on the disperse-impulse input of energy in heterogeneous environments mechanisms. It uses processes of adiabatic boiling and cavitation with sharp pressure differences, combined with heating and cooling of the fluid flow. The technology allows to obtain a number of new effects due to changes in the properties of treated liquids.

Principal scheme of thermo-vacuum technology for processing/

COMPLEX OF INVESTIGATIONS OF WATER PROPERTIES IN THE CONDITIONS OF DISPERSE-IMPULSE INPUT OF ENERGY IN HETEROGENEOUS ENVIRONMENTS PROCESSING

The properties of water in the treatment of thermo-vacuum technology and during the influence of high-frequency hydrodynamic oscillations are investigated. Water is considered as a substance existing in nature, with its impurities and inclusions.

As a result of research, the following was established:

– a number of physical and thermophysical parameters of water are changing such as: electrical conductivity, galvanic current, specific heat of vaporization, kinematic viscosity;

– the chemical composition of impurities of primary water changes, general hardness, total alkalinity, mass concentration of hydrocarbons decreases. The microstructure and fractional composition of impurities changes, the dispersion and structure increase;

– the most significant change in the value of the hydrogen index (pH). In experiments, it reached values 9-9.2 at an initial value of 6.8-7;

– the fundamental achievement is that the state of elevated pH is maintained for a long time over several years. The results obtained are the basis of a number of technologies aimed at creating products with new qualities and on solving some environmental problems.

TECHNOLOGY AND EQUIPMENT FOR NON-REAGENT NEUTRALIZATION OF CONDENSATE OBTAINED AFTER NATURAL GAS COMBUSTION

In developing the technology of non-reagent neutralization of acid solutions, the property of water used to increase the hydrogen index (pH) in the treatment of disperse-impulse input of energy in heterogeneous environments condition was used. To implement the technology, special equipment has been developed that is designed for operation in the boiler circuit, in combination with a condensation type utilizer for the neutralization of acid condensate, which is formed by combustion of natural gas in a boiler in the mode of deep cooling of waste gases. The equipment provides a non-reagent way of neutralization.

Two types of plants of different productivity, which can be used with medium power boilers, with one or several (up to three), are developed. They operate in continuous mode and are equipped with an automation system that controls the pH, performance, temperature and pressure.

The use of a condensation mode for cooling off exhaust flue gases in combination with non-reagent neutralization of condensate can reduce the negative environmental load, boost boiler efficiency, reduce gas consumption and consumption of natural water.

INNOVATIVE PROJECT “DEVELOPMENT, MANUFACTURE AND IMPLEMENTATION OF A PROFESSIONAL INDUSTRIAL SAMPLE FOR WOOD AND WATER / SPIRIT MIXTURE OF PRODUCTIVITY 1 T / HOUR”

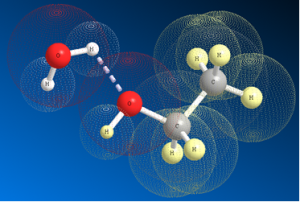

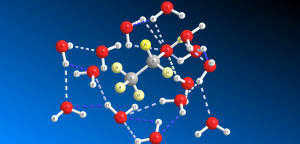

A new technology for the production of water-alcohol mixtures (solutions), which includes pre-treatment of water by the influence of high-frequency hydrodynamic oscillations, is further developed, with further mixing with alcohol, also in the high-frequency hydrodynamic oscillations mode. This treatment provides the “structured” water with improved organoleptic properties and a water-alcohol mixture with an increased degree of hydration. Within the framework of the project, experimental research and modeling of the process of hydration of ethanol molecules by water molecules was carried out, which allowed to determine the main parameters of the process of obtaining a water-alcohol mixture in the production of vodka. The proposed technological scheme and equipment for the implementation of technology, which have a number of technical and economic advantages: improving the quality of the finished product, the possibility of increasing productivity, maintaining the process in continuous mode and reducing the amount of large-sized equipment, ensuring the tightness of the process.

The technology and equipment have undergone an industrial test and are implemented at one of the enterprises of the liqueur industry.

|

|

|

| The mechanism of formation of hydrogen bonds between molecules of alcohol and water | The molecule of alcohol is hydrated with water molecules | Formation of clathrate |

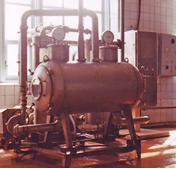

TECHNOLOGY AND EQUIPMENT FOR PROCESSING OF MILK

The dairy industry has traditionally been concerned with increasing the quality of raw materials and finished products. In accordance with a number of Decisions of the State Authorities of the Ukrainian SSR and the USSR in the ITT NAS of Ukraine, four modifications were developed for the milk processing technology and equipment. At three machine-building plants, mass production of these machines was organized. Implementation of this development allowed to increase the shelf life of drinking milk up to 14 days, to increase its quality due to deodorization, decrease of acidity, increase of thermal stability, soft homogenization, suppression of microflora.

The complex of works on the study of the properties of milk, the creation of equipment for its processing and introduction at dairy enterprises awarded the State Prize of Ukraine in the field of science and technology.

Developed normative and technical documentation:TU 88 RSFSR 066.002-89 “Homogenizer vacuum Vg-5”; TU U 15.5-05417118.023-2002 “Milk Cow”.

The technology and equipment for the production of milk with an extended shelf life have been introduced in more than 50 dairy enterprises of Ukraine, Bulgaria, Russia, including dairies in Kyiv, Lviv, Ternopil, Simferopol, Sumy, Donetsk and others.

TECHNOLOGY AND EQUIPMENT FOR VACUUM HOMOGENIZATION OF MILK IN MANUFACTURE OF ACID POWDER, GRAPE AND YOGURTS

Apparatus type VG-5 continue to be widely used in the production of sour-milk products in order to improve quality and reduce energy consumption. The quality of products increases due to deep deodorization of raw materials, suppression of foreign microflora, and soft homogenization. Energy expenditure is reduced in comparison with the use of valve homogenizers in 3 times (8 kW per 1 ton of product with valve homogenization against 2.5 kW per 1 ton of product in vacuum homogenization). By this technology produced kefir, dairy product “Narine”.

TECHNOLOGY OF VACUUM HOMOGENIZATION IN THE MANUFACTURE OF SUGARING OF DAIRY CONSERVES

Technology and apparatus of the type VG-10 are introduced on a number of dairy factories that produce canned milk. Their implementation allowed to improve the quality of products, reduce the deposition of fat and increase the shelf life.

Developed normative and technical documentation:TU U 15.5-05417118.031-2004 “Milk Products Condensed with Sugar Recombined”.

| Specifications | DV-5 | DV-10 |

| Productivity, liter per hour

Milk temperature at the input, ° С Temperature of heat treatment of milk, ° С Installed capacity, kW Overall dimensions, mm Weight, kg, no more |

5 000

4 – 10 70 – 95

16,5 1300х1100х1400 300 |

5 000

4 – 10 70 – 95

27,5 1500х1200х1450 450

|

COMPLEX OF RESEARCHES ON THE DEVELOPMENT OF TECHNOLOGY OF EMULSION OF DAIRY-FATTY MIXTURES

A fundamentally new method of emulsification of immobilizing liquids based on adiabatic boiling in a stream of mixtures of various composition in a wide range of concentrations, temperatures and pressures is proposed. Experiments used fats of animal origin, culinary and vegetable fats, emulsifying and stabilizing components, admitted in veterinary medicine. As a result of the research, the emulsification process, the concentration and temperature parameters, the microstructural characteristics of the mixtures of various compositions were established. Based on the obtained data, the main provisions of the technology and the principal scheme of equipment for its realization, developed in the production of substitutes for whole milk for animals, were developed.

Two modifications of vacuum emulsifiers were developed to produce emulsions in the production of liquid and dry substitutes for whole milk.

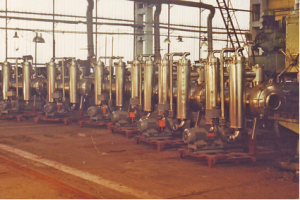

TECHNOLOGY AND EQUIPMENT FOR MANUFACTURE OF LIQUID SUBSTITUTES OF UNSUPPED MILK

The ITTF of the National Academy of Sciences of Ukraine developed a fundamentally new technological process for the production of a liquid substitute of whole milk and a set of measures on interaction between dairy industry and agriculture in the organization of delivery and consumption of the product. To implement the project, special equipment was developed for obtaining high-quality milk and fat emulsions – a vacuum emulsifier of type EB and a technological line for receiving liquid ZNM. A mass production of vacuum emulsifiers and auxiliary equipment was organized. A large-scale implementation was implemented in Ukraine, Belarus, Russia, Bulgaria. In total, more than 500 technological lines were introduced.

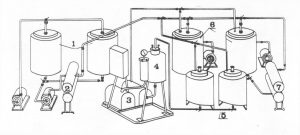

Scheme of the technological line of production of liquid ZNM

1 – milk container; 2 – pasteurizer; 3 – vacuum pump; 4 – vacuum emulsifier; 5 – capacity for preliminary mixing; 6 – the capacity of the finished product; 7 – cooler.

The complex of works on creation of technology of production of liquid ZNM and organization of its large-scale implementation was awarded the State Prize of Ukraine in the field of science and technology.

| Technology and equipment for liquid ZNMs were presented at the USSR Academy of Medical Sciences and awarded the Golden Medal. |  |

Map of introduction of technological lines for the production of liquid ZNM at dairies and agricultural enterprises of Ukraine

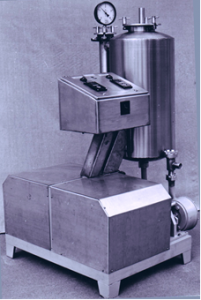

TECHNOLOGY AND EQUIPMENT FOR HIGH-DISTILLED EMULSIONS FOR MANUFACTURE OF DRIED BUTTERS OF UNCERTAINTED MILK

Emulsification of the milk-fat mixture is one of the main technological operations in the production of dry CZN, which determine the quality of the finished product. The TDS ITTF Department of the National Academy of Sciences of Ukraine developed the technology and special equipment of the type of EMU to obtain highly stable concentrated milk and fat emulsions, which allowed to significantly improve the quality of dry CER and reduce energy consumption for its production. Serial production of EMU devices and their wide introduction was organized. In Ukraine, at least 20 devices were introduced at dairy enterprises, which produced dry CZM.

Apparatus for emulsification of concentrated milk and fat mixtures (EMC) was presented to the Aviation Academy of the USSR and awarded the Golden Medal.

PROJECTS FOR FOOD INDUSTRY

TECHNOLOGY AND EQUIPMENT FOR SODIUM HOMOGENIZATION

At the request of Vinnifruit, a technological line for the homogenization of tomato juice was developed and implemented. The main working line of the technological line is a rotary-impulse device, developed in the TDS department specifically for this product.

TECHNOLOGY AND EQUIPMENT FOR RECONSTRUCTION OF WASTEWATER MANUFACTURE

The work was carried out at the request of the Kiev enterprise “Refrigerator №4”. In the production of ice cream in the manufacture of waffle cups and plates a significant amount of broken product, which goes for re-use. The quality of the wafer from the secondary raw material depends on the degree of homogenization of the soaked laminate product. For this purpose (homogenization) it was proposed to use the rotary-impulse apparatus of the CRIC-3. As a result of the implementation of the work, the quality of the wafer was improved and the amount of waste was reduced.

EQUIPMENT FOR RENDERING DRIED BOTTLE FORMS OF FOODSTUFFS

The food industry is widely used to dissolve powder-like products. The main problem in its implementation is the completeness of the product dissolution, which is determined by the effectiveness of the interaction of the product and the solvent. For this purpose, the TDS department developed a technological line and a special device for dissolving powdered products. Tests and technology implementation are carried out at dairy factories in Kiev for the recovery of dry milk.

|

Specifications:

Productivity, t per hour – 10 Power consumption, kW – 1,5 Weight, kg – 95 Dimensions, mm – 600x700x1100 |

EXTRUSION TECHNOLOGIES

Extrusion technologies are widely used in various industries, in particular, processing industry for food and agriculture. This is due to the possibility of combining in one machine processes of grinding, homogenizing and heat treatment of raw materials, and as a consequence, the possibility of obtaining a wide range of products. For agricultural purposes, extruders operating at low temperatures and pressures are most commonly used. Our technologies use extruders, which work exclusively in the mode of hot extrusion, which proceeds at high temperatures, speeds and pressure, and a significant transition of mechanical energy into heat. In such modes, before exiting the filter, the processed material is compressed to the maximum and warmed up to the maximum temperature. When leaving the filter as a result of a sudden drop in pressure there is an instant destruction of the cell structure, evaporation of moisture, which is accompanied by the release of a significant amount of heat from the extrudate. As a result of this processing the product acquires a new structure and high biological nutrition. For the first time, it is proposed to use the heat of extrusion, which loses the extrudate at the outlet of the filter for mixing the components at the receipt of pastes and for spraying in obtaining granular mixtures, which allows solving the problem of rational use of energy resources.

TECHNOLOGY OF RECEIVING PASTE-LIKE PLANT MIXTURES

The technology includes the following operations: 1 – extrusion processing of the grain component as a result of which in the grain component there are profound changes in the structure of nutrients: starch breaks down into simple sugars, proteins are denatured, decontaminates harmful microflora; 2 – preparation of liquid components in a given ratio; 3 – mixing the extrudate with liquid components, performed in a specially designed device. Device 3 allows you to dispose of the heat of extrusion, which loses extrudate at the exit of the apparatus and significantly reduce energy costs compared with existing technologies for obtaining moist feed.

Equipment for obtaining multicomponent paste-like mixtures of vegetable origin.

This equipment is intended for the preparation of feed for farm animals. Now it is in the stage of finalization.

TECHNOLOGY OF RECEIVING GRANULATED FERTILIZER MIXTURES

The technology includes the following operations: 1 – extrusion processing of the grain component and 2 – spraying of the powder component to the extrudate, which is implemented in a specially designed device, which allows the use of heat of extrusion that loses the extrudate at the outlet of the apparatus for the spraying process.

Installation for granular mixtures.

The technology is intended for the preparation of feed for poultry. Is in the stage of finalization.

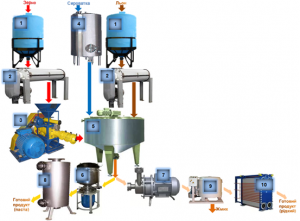

UNIVERSAL TECHNOLOGICAL LINE FOR MANUFACTURE OF LIQUID AND PASTE-LIKED MULTI-COMPONENT MIXTURES ON THE GRAIN BASIS

The technology includes the following operations:

– preparation of grain components and extractant in special containers;

– humidifying of grain components with the help of a humidifier;

– extrusion of soybeans;

– method of disperse-impulse input of energy in heterogeneous environments treatment using the devices in which the mechanisms of disperse-impulse input of energy in heterogeneous environments are implemented: rotor-pulsating apparatus and cavitation-type disperser;

– pasteurization of the product (liquid and paste) in heat exchangers;

– separation of liquid product from cake in a centrifuge.

The technology is intended for the food industry (in particular for bakery products, functional beverages) and agro-industrial complex.

Technology is in the stage of finalization.

1 – capacity for grain components; 2 – grain humidifier; 3 – extruder; 4 – capacity for extractant; 5-7 – devices using the DIVE mechanisms; 8, 10 – heat exchangers; 9 – centrifuge.

PROJECTS FOR MEDICAL INDUSTRY

Technologies and equipment for suspension concentration of high-termolable solutions

– technology of azeotropic evaporation of crystallizing solutions of antibiotics. The technology was designed to concentrate solutions of penicillin;

– technology and equipment for spray evaporation of aqueous-alcoholic solutions of insulin in the environment of a neutral gas coolant in the circuit;

-technology and equipment for concentration and drying of enzyme solutions (hygrolitin, amigluratsil);

-technology of liquid extraction with a fast-flexible chemical reaction;

-technology and equipment for receiving sterile emulsions for medical industry;

DRAFT FOR CABLE INDUSTRY

TECHNOLOGY AND EQUIPMENT FOR MANUFACTURE OF POTATOING COOLING LIQUIDS

On the basis of the rotary-impulse apparatus, an installation was developed for obtaining cooling emulsions from technical fats and sodium oleate. Such emulsions are used in the cable industry during wire drawing for lubrication and cooling. Plants were introduced not less than 20 cable factories in Ukraine and abroad.

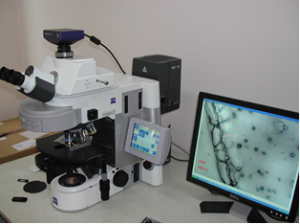

MATERIAL AND TECHNICAL BACKGROUND OF THE LABORATORY

The material and technical background of the laboratory consists of 8 experimental stands, the chemical laboratory and the laboratory of microstructural studies.

|

|

Universal experimental stend for extrusion dispersion and multi-component mixes

MAIN PUBLICATIONS

Monographs

- Долинский А.А., Басок Б.И., Гулый С.И., Накорчевский А.И., Шурчкова Ю.А. Дискретно-импульсный ввод энергии в теплотехнологиях. — Киев: Научная книга, 1996. — 208 с.

- Шурчкова Ю.А. Адиабатное вскипание. Практическое использование / Шурчкова Ю.А. – К. : Наукова думка, 1999. – 278 с.

Chapters of monographs

- Liubov Gozhenko, Georgii Ivanitskyi, Bogdan Tselen, Natalia Radchenko, Anna Nedbailo. Application of the method of discrete input pulse energy for energy-efficient production of Chelidonium majus extract. / Chemical Technology and Engineering: Monograph. (Atamanyuk V.M. et al., Eds.) – Lviv: SPOLOM, 2021. Pp. 96–98. DOI: http://doi.org/10.23939/cte. URL: http://cte.org.ua/3rd-chemical-technology-engineering-2021/monograph

- Gozhenko, L., Radchenko, N., Ivanytskyi, H., Lymar, A., Sydorenko, V., Tselen, B., & Obodovych, O. (2021). Discrete-Pulsed Energy Input in Water Treatment Technology. Scientific Environment of Modern Human, 1(sua19-01), 47–62. https://doi.org/10.30888/2663-5569.2021-19-01-008

Articles

- Ромоданова В.А., Шурчкова Ю.А., Бабенко О.Б. Сучасний погляд на процеси обробки молока // Молочна промисловість, № 8. – 2005.

- Долинский А.А. Изменение микроструктуры сухого остатка воды при различных способах её обработки / Долинский А.А., Шурчкова Ю.А.,Сланик А.В. // Пром. теплотехника. – 2009. – Т.31, №7. – С.86 – 89.

- Шурчкова Ю.О. Исследование влияния дискретно-импульсного ввода энергии на физико-химические показатели воды / Шурчкова Ю.О., Коник А.В. // Пром. теплотехника. – 2009. –Т.31, №3. – С.108–112. 3. Коник А.В. Дослідження водневого показника води і його вплив на відновлення фруктових напоїв / Коник А.В. // Наукові праці. – 2008. – № 32. – С. 251–255.

- A Shurchkova. Studying of the effects DPIE influence on chemical parameters of water and change hydrogen parameter pH / J.A Shurchkova, A.V.Konyk// in journal ”Biotechnology, Biodegradation, Water and Foodstaffs” published by Nova Science Publishers . Inc. New York. 2009 – p.131–134.

- Шурчкова Ю.А. Новая технология переработки молока // Журнал Переработка молока, Москва, 2006.

- Долинский А.А., Шурчкова Ю.А. // Инновационные технологии для молочной промышленности. Молочное дело, №1. – 2005.

- Шурчкова Ю.А. Экологически чистый способ снижения кислотности и повышения качества молочного сырья // Молочное дело, № 7, 2005.

- Шурчкова Ю.А., Ганзенко В.В., Маркин А.В. Первичная обработка молока на малых фермах. Молочна промисловість, №1. – 2003.

- Иваницкий Г.К. Аналитическое исследование кавитации в рабочем колесе центробежных насосов / Г.К. Иваницкий, А.Е. Недбайло // Промышленная теплотехника. – 2012. – Т. 34, №2. – С. 40 – 47.

- Иваницкий Г.К. Использование гидродинамической кавитации для разрушения бактериальных клеток в технологии обработки молока / Г.К. Иваницкий, Ю.А. Шурчкова, А.Е. Недбайло // Промышленная теплотехника. – 2012. – Т. 34, №3. – С. 31 – 39.

- Шурчкова Ю.О. Вплив технологій ДІВЕ на властивості води і молока / Ю.О. Шурчкова, А.В. Коник, А.Є. Проценко // Наукові праці ОНАХТ. – 2007.– № 30. – С. 116 – 119.

- Шурчкова Ю.О. Вплив нового способу термомеханічної обробки на технологічні властивості молока. / Ю.О. Шурчкова, В.О. Ромоданова, А.Є. Недбайло //Наукові праці ОНАХТ. – 2007. – №31, том 2. – С. 180 – 183.

- Шурчкова Ю.А. Повышение качества молока при термовакуумной обработке / Ю.А. Шурчкова, В.А. Ромоданова, А.Е. Недбайло // Наукові праці ОНАХТ. – 2007. – № 32. – С. 116 – 119.

- Шурчкова Ю.А. Особенности состава микрофлоры молока при разных способах обработки / Ю.А. Шурчкова, В.А. Ромоданова, В.В. Ганзенко, А.Е. Недбайло // Наукові праці ОНАХТ. – 2010. – № 37. – С. 166 – 170.

- Шурчкова Ю.О. Фракційний склад білків та термостійкість молока в залежності від різних способів обробки / Ю.О. Шурчкова, В.О. Ромоданова, О.М. Савчук, А.Є. Недбайло // Молочна промисловість. – 2008. – №2. – С. 37 – 41.

- Ромоданова В.А. Изменение редокс-потенциала молока в процессе его обработки / В.А. Ромоданова, Ю.А. Шурчкова, А.Е. Недбайло // Молочна промисловість. – 2009. – №4 (53). – С. 22 – 23.

- Ромоданова В.О. Зміни колоїдної системи білків молока при термовакуумній обробці / В.О. Ромоданова, Ю.О. Шурчкова, А.Є. Недбайло // Вісник аграрної промисловості. – 2009. – №1. – С. 61 – 63.

- Шурчкова Ю.О., Ганзенко В.В., Шаркова Н.О. Заменитель цельного молока „Лактocоя”// Молочна промисловість. – 2003. – № 6 (9). – C. 22-23.

- Ганзенко В.В. Прогресивна відгодівля замінниками молока // Тваринництво України. – 2005. – № 18. – C. 5 – 6.

- Ганзенко В.В. Соєві боби. Вплив способу, ступеня їх подрібнення і термообробки на технологічні властивості водяних суспензій // Харчова промисловість. – 2005. – № 8. – С. 24 – 25.

- Шурчкова Ю.О., Ганзенко В.В. Новая технология заменителя цельного молока // Молочное дело. – 2006. – № 7. – С. 47 – 49.

- Ганзенко В.В. Гранульовані й пастоподібні премікси можна отримувати в одному екструдері // Зерно і хліб.- 2011.- №2. – С.37.

- Шурчкова Ю.А., Ганзенко В.В., Радченко Н.Л. Экструзионный метод обработки зерна сои // Хранение и переработка зерна. – 2007. – № 9. – С.51–53.

- «Особливості якісних змін білкового складу молока в процесі термовакуумної обробки» Д.т.н. Шурчкова Ю.О., к.т.н. Ромоданова В.О., Недбайло А.Є., Целень Б.Я. // Харчова і переробна промисловість. № 1 (353), січень 2009. – С. 25–27.

- Пути снижения энергетических затрат в технологии термомеханической обработки биологически активных продуктов. Иваницкий Г.К., Целень Б.Я., Недбайло А.Е. // Промышленная теплотехника. Том 30, № 6, 2008. – С. 84–88.

- Тепло- и массообмен при испарении и конденсационном росте капель в воздухе и в перегретом паре. Иваницкий Г.К., Целень Б.Я. // Промышленная теплотехника. Том 31, № 6, 2009. – С. 56–63.

- Распределение температуры в объеме сферической капли в процессе нестационарного испарения. Иваницкий Г.К., Целень Б.Я. // Промышленная теплотехника. Том 31, № 7, 2009. – С. 117–121.

- Оптимизация тепломассообменных и гидродинамических процессов в технологии термовакуумной обработки молока. А.А. Долинский, Ю.А. Шурчкова, Г.К. Иваницкий, Б.Я. Целень // Наука та інновації. Т.6, №1, 2010. – С. 59–69.

- Оптимизация работы аппарата термовакуумной обработки с точки зрения энергосбережения. Целень Б.Я., Иваницкий Г.К. // Наукові праці ОНАХТ. Випуск 39, Т.2, 2011. – С. 245-249.

- Вплив адіабатного закипання та кавітації на фізико-хімічні показники молока при його обробці за термовакуумною технологією. Шурчкова Ю.О., Целень Б.Я., Недбайло А.Є., Іваницький Г.К. // Наукові праці ОНАХТ. Випуск 40, Т.2, 2011. – С. 263–266.

- Енергозбереження в апаратах термовакуумної технології. Целень Б.Я. // Наукові праці ОНАХТ. Випуск 41, Т.2, 2012. – С. 31–34.

- Якісні та енергетичні аспекти використання термовакуумної технології для обробки молока. Іваницький Г.К., Целень Б.Я., Недбайло А.Є. // Наукові праці ОНАХТ. Випуск 42, Т.2, 2012. – С. 301–304.

- Оцінка якості диспергування рідини в апаратах термовакуумної обробки. Целень Б.Я. // Наукові праці ОНАХТ. Випуск 43, Т.2, 2013. – С. 82–86.

- Дубовкина И.А. Исследование влияния эффектов ДИВЭ при обработке воды и водно-этанольных смесей / И.А. Дубовкина // Вост.-Европ. журн. передовых технологий . – 2012. – № 1/8. – С. 4-6.

- Дубовкина И.А. Моделирование процессов гидратации и структурирования этанола в условиях обработки ДИВЭ / И.А. Дубовкина // ВЕЖПТ . – 2012. – № 2012 – 6/6 (60) С 50-52.

- Ю.А. Шурчкова Н.Л. Радченко. Теоретичне дослідження гідродинамічних та теплообмінних процесів, що протікають в каналі перед матричної і матричної зон екструдера // Наукові праці ОНАХТ том 2 випуск №43,2013Технічні науки. – С. 7-10 м. Одеса 2013р.

- Н.Л.Радченко. Математична модель гідродинамічних та теплообмінних процесів в передматричній і матричній зонах екструдера при обробці рослинної сировини // Наукові праці ОНАХТ том 1 випуск №41,2012 Технічні науки. – С. 179-181 м. Одеса 2012р.

- Г.К. Иваницкий, Ю.А. Шурчкова, Н.Л. Радченко Моделирование процесса экструзии в предматричной зоне и в матрице при обработке растительного сырья // Промышленная теплотехника. 2011, №6 Т. 33 С.32-38.

- Ю.О. Шурчкова, В.В. Ганзенко, Н.Л. Радченко Реалізація енергозберігаючих технологій в кормо виробництві // Науковий вісник національного університету біоресурсів і природокористування України №153 2010 С.70-75.

- А.А. Долінський, Ю.О. Шурчкова, В.В. Ганзенко, Н.Л. Радченко. Технологія отримання замінника незбираного молока для відкорму сільськогосподарських тварин на основі екструдера // Наукові праці ОНАХТ випуск №37, 2010 Технічні науки. – С. 341-343.

- Ю.О. Шурчкова, В.В. Ганзенко, Н.Л. Радченко. Замінник незбираного молока за новою технологією // “Тваринництво України”. – 2009. – №6, С.10-12.

- Ю.О. Шурчкова, В.В. Ганзенко, Н.Л.Радченко. Протеїновий корм для птиці // “Тваринництво України”. 2009 №5 C. 35-37.

- Ю.А. Шурчкова, В.В. Ганзенко, Н.Л. Радченко. Экструзионный метод обработки зерна сои // «Хранение и переработка зерна» 2007 №9 (99) С.51

- Ю.А. Шурчкова, Н.Л. Радченко. Экструзионные методы переработки растительного сырья // Наукові праці ОНАХТ випуск № 30, 2007 Технічні науки м. Одеса. – 2007. – С. 124 – 126.

- Долинский А.А. Исследование процесса эмульгирования при адиабатическом вскипании многокомпонентных систем / А.А. Долинский, Ю.А. Шурчкова, В.К. Буримский // Молочная промышленность. – 1986. – № 10. – С. 15–18.

- Шурчкова Ю.А. Новый класс аппаратов для диспергирования жидкостей путем дискретно-импульсного ввода энергии / Ю.А. Шурчкова // Промышленная теплотехніка. – 1998. – № 3. – С. 14–18.

- Шурчкова Ю.А. Вакуумная гомогенизация при производстве сгущенных молочных консервов / Ю.А. Шурчкова, В.А. Ромоданова, О.В. Кочубей, Н.К. Кононенко // Промышленная теплотехника. – 1998. – Т. 20, № 1. – С. 16–18.

- А.А. Долінський, Ю.А. Шурчкова. Вода в условиях обработки ДИВЭ // Доповіді НАН України. — 2013, №9.с 93-100.

- Іваницький Г.К. Дослідження впливу кавітаційного механізму при пульсаційному екстрагуванні рослинної сировини для технології переробки насіння / Г.К. Іваницький, Ю.О. Шурчкова, В.В. Ганзенко, Л.П. Гоженко, Т.І. Янюк , Т.О. Янюк, О.Ю. Бондар // Наукові праці ОНАХТ ¬– 2014.- Вип. 42.–Т.2, С. 263–266

- Иваницкий Г.К. Аналитическое исследование условий возникновения кавитации в трубе пульсационного диспергатора ударного типа./ Г.К. Иваницкий, Л.П. Гоженко // Пром. теплотехника.–2014.–Т.36, №6 С. 49-56

- Іваницький Г.К. Застосування кавітаційного реактора пульсаційного типу для екстрагування з рослинної сировини [Текст]/ Г.К. Іваницький, О.І. Чайка, Л.П. Гоженко //Наукові праці Одеської національної академії харчових технологій. Одеса, 2015. – вип.47, Т.2, с. 138 – 142

- Експериментальні дослідження екстрагування з рослинної сировини методом дискретно-імпульсного введення енергії / О.І.Чайка, К.Д.Малецька, М.В. Матюшкін, Л.П. Гоженко // Наукові праці ОНАХТ Міністерство освіти і науки України. – Одеса: 2012. – Вип. 41. – Том 1. – с. 48 – 51

- Коник А.В. Дослідження впливу механізмів ДІВЕ на зміну фізико-хімічних властивостей води, молока та при відновленні сухих молочних продуктів /Коник А.В.// Наукові праці. – 2015. – Т.1, № 47. – С.110–113.

- Коник А.В. Обзор и анализ международных нормативных документов, определяющих уровень безопасности и качества питьевой воды / Коник А.В.// Промышленная теплотехника. – 2015. – Т.37, №5. – С.87 – 95.

- Коник А.В. Технологические параметры воды и их влияние на керамические поверхности воды. Вода, обработанная методом дискретно-импульсного ввода энергии /Коник А.В.// Международный НПЖ Керамика: Наука и жизнь. – 2015. – Т3, №28. – С. 41-48

- Коник А.В. Дослідження впливу високочастотних гідродинамічних коливань на водневий показник водних систем /А.В. Коник, А.А. Долинский Ю.А. Шурчкова, И.А. Дубовкина// Международный НПЖ Керамика: Наука и жизнь. – 2014. – Т4, №25. – С. 51-57

- Коник А.В. Дослідження впливу механізмів дискретно-імпульсного введення енергії на водневий показник водних систем / А.В. Коник, А.А. Долинский, Ю.А. Шурчкова, И.А. Дубовкина // Промышленная теплотехника. – 2015. – Т.37, №1. – С.5 – 11.

- Коник А.В. Вплив механізмів дискретно-імпульсного введення енергії на буферні властивості води /А.В. Коник, А.А. Долинский, Ю.А. Шурчкова, Н.Л. Радченко// Промышленная теплотехника. – 2015. – Т.37, №7. – С. 87 – 95.

- Исследование влияния кавитации на качество эмульсии при получении топливных композиций. Щепкин В.И., Целень Б.Я., Радченко Н.Л. // Наукові праці ОНАХТ. Випуск 45, Т.3, 2014. – С. 196–199.

- Нейтралізація кислих водних розчинів методом дискретно-імпульсного введення енергії. Целень Б.Я., Яроцький С.М. // Наукові праці ОНАХТ. Випуск 45, Т.3, 2014. – С. 34–39.

- Технология и оборудование для нейтрализации кислых стоков. Долинский А.А., Шурчкова Ю.А., Целень Б.Я.// Промышленная теплотехника. Том 36, № 5, 2014. – С. 98–105.

- Перспектива використання способу дискретно-імпульсного введення енергії для нейтралізації кислих водних розчинів. Яроцький С.М., Целень Б.Я. // Промышленная теплотехника. Том 37, № 4, 2015. – С. 23–30

- Спосіб безреагентної нейтралізації кислого конденсату продуктів згоряння природного газу. Целень Б.Я. // Наукові праці ОНАХТ. Випуск 47, Т.2, 2015. – С. 109–111.

- Оптимизация тепломассообменных и гидродинамических процессов в технологии термовакуумной обработки молока. Долинский А.А., Шурчкова Ю.А., Иваницкий Г.К., Целень Б.Я. // Микро- и наноуровневые процессы в технологиях ДИВЭ: Тематический сборник статей / под общей ред. А.А. Долинского; Институт технической теплофизики НАН Украины. – К. : Академпериодика, 2015. – 464 с., 24 с. ил. (С. 136–147; УДК 536.24; ББК 30.13; М 59; ISBN 978-966-360-291-2).

- Безреагентна нейтралізація кислого конденсату продуктів згоряння природного газу та обладнання для її нейтралізації. Долінський А.А., Шурчкова Ю.О., Целень Б.Я. // Микро- и наноуровневые процессы в технологиях ДИВЭ: Тематический сборник статей / под общей ред. А.А. Долинского; Институт технической теплофизики НАН Украины. – К. : Академпериодика, 2015. – 464 с., 24 с. ил. (С. 343–350; УДК 536.24; ББК 30.13; М 59; ISBN 978-966-360-291-2).

- Современные методы очистки и нейтрализации промышленных стоков. Долинский А.А., Шурчкова Ю.А., Радченко Н.Л//Промышленная теплотехника. Том 36, №6, 2014. – С.89–106.

- Новые подходы в области очистки промышленных сточных вод Радченко Н.Л.//Наукові праці ОНАХТ. Випуск 47, Т.1, 2015. – С. 52–57

- Dolinsky, A. Konyk, N. Radchenko, B. Tselen. Influence of Adiabatic Boiling on Water рH Value. (2016). Scientific Works of National University of Food Technologies, Vol. 22, No. 4, 128–133. URL: http://sw.nuft.edu.ua/Archiv/2016/swnuft_22_4.pdf

- Dolinskiy, A., Tselen, B., Hartvih, A., Konyk, A., Radchenko, N., & Shchepkin, V. (2017). The Formation of Acidic Condensate During Deep Heat Utilization from Natural Gas Combustion Products and the Apparatus of Its Neutralizing. Scientific Works, 80(1), 4–8. https://doi.org/10.15673/swonaft.v80i1.191

- A. Dolinsky, A. Konyk, N. Radchenko, B. Tselen. Influence of Adiabatic Boiling on the Properties of Water. (2016). Scientific Works of National University of Food Technologies, Vol. 22, No. 5, 126–133. URL: http://sw.nuft.edu.ua/Archiv/2016/swnuft_22_5.pdf

- Tselen B., Stolitnia N. Influence of the Discrete-Pulse Input of Energy on pH of the Acidic Solution. (2017). International scientific journal “Internauka”. № 6 (28), 72–77. URL: https://www.inter-nauka.com/issues/2017/6/2431

- Dolinskiy, A., Tselen, B., Ivanitsky, G., Konyk, A., Radchenko, N., & Hartvih, A. (2017). Using of the Energy Discrete-Pulse Input Method for the Condensate Natural Gas Combustion Products Neutralizing. Scientific Works, 81(1), 9–14. https://doi.org/10.15673/swonaft.v81i1.663

- Hozhenko, L., Konyk, A., Radchenko, N., Tselen, B., & Nedbailo, A. (2017). Application Energy-Efficient Equipment for Obtaining Celandine Extract. Scientific Works, 81(1), 65–70. https://doi.org/10.15673/swonaft.v81i1.677

- Dolinskiy, A., Konyk, A., Radchenko, N., Tselen, B., & Gozhenko, L. (2017). Perspectiveness and Development of Apparatus the Principle of Work Is Based on the Mechanisms of Discrete-Pulse Energy Input. Thermophysics and Thermal Power Engineering, 39(5), 7-11. https://doi.org/10.31472/ihe.5.2017.01

- Ivanitsky, G., Tselen, B., Nedbailo, A., & Konyk, A. (2019). Study of Liquid Degassing in Cavitating Flows. Problems of Modeling. Scientific Works, 83(1), 129–134. https://doi.org/10.15673/swonaft.v83i1.1430

- Modeling the kinetics of cavitation boiling up of liquid. Ivanitsky G.K., Tselen B.Ya., Nedbaylo A.E., Konyk A.V. // Physics of Aerodisperse Systems. – 2019. – № 57. – С. 136–146. DOI: http://dx.doi.org/10.18524/0367-1631.2019.57.191970.

- Ivanitsky G.K., Tselen B.Ya., Konyk A.V., Nedbaylo A.E. The use of cavitation methods for cleaning water from aggressive gases // Materials of the XXVIII International Scientific Conference “Dispersed Systems” – Odessa: ONU, 2019. –P. 45–46.

- Demchenko V., Tselen B., Konyk A., Ivanov S. Research of Thermal Cycling of Organic Substances with Phase Transition. (2020). Scientific-Discussion # 41, 54–58. URL: http://scientific-discussion.com/wp-content/uploads/2020/04/VOL-1-No-41-2020.pdf

- Ivanitsky, G., Tselen, B., Nedbaylo, A., & Gozhenko, L. (2020). The Ways of Producing a Unified Mathematical Model for the Cavitating Flow in Hydrodynamic Cavitation Reactors. Thermophysics and Thermal Power Engineering, 42(2), 31-38. DOI: https://doi.org/10.31472/ttpe.2.2020.3

- The current state of air pollution by thermal power plants and ways to reduce harmful emissions. Dolinskyi А.А., Konyk A.V., Radchenko, N.L., Tselen B.Ya. (2019). International scientific journal “Internauka”. № 8 (70), Volume 2, 28–35. https://doi.org/10.25313/2520-2057-2019-8

- Tselen, B., Gozhenko, L., Radchenko, N., & Ivanitsky, G. (2020). Use of cavitation effects in extraction processes. Scientific Works, 84(1), 92-97. https://doi.org/10.15673/swonaft.v84i1.1876

- Ivanitsky, G., Tselen, B., Radchenko, N., & Gozhenko, L. (2021). Analytical Study of the Mechanism of Droplet Deformation and Breakup in Shear Flows. Thermophysics and Thermal Power Engineering, 43(1), 30-37. https://doi.org/10.31472/ttpe.1.2021.4

- Ivanitsky, G., Tselen, B., Ganzenko, V., & Radchenko, N. (2021). Prospects of using naked oats in gluten-free dietary products. Experimental investigation of the grain structure changes during extrusion processing. Scientific Works, 85(1). https://doi.org/10.15673/swonaft.v85i1.2063.

- Obodovych O., Tselen B., Sydorenko V., Ivanytskyi H., Radchenko N. Discrete-pulse energy input and its implementation in water treatment technology // Modern directions of scientific research development. Proceedings of the 8th International scientific and practical conference. BoScience Publisher. Chicago, USA. 2022. Pp. 278-282. URL: https://sci-conf.com.ua/viii-mezhdunarodnaya-nauchno-prakticheskaya-konferentsiya-modern-directions-of-scientific-research-development-26-28-yanvarya-2022-goda-chikago-ssha-arhiv/

- Dolinskyi, A., Obodovych, O., Tselen, B., Sydorenko, V., Ivanytskyi, G., Lymar, A. & Radchenko, N. (2022). Intensification of Water Treatment Technology by Discrete-Pulse Energy Input. SWorldJournal, 1(11-01), 56–61. https://doi.org/10.30888/2663-5712.2022-11-01-080

- Tselen B. Ya., Radchenko N .L., Ivanytskyi H.K., Pereiaslavtsev O.M., Shchepkin V.I., Shulyak V.V. (2022). Features of Wastewater Treatment in Cavitation Flows. Modern engineering and innovative technologies, 1(19-01), 52–56. https://doi.org/10.30890/2567-5273.2022-19-01. URL: https://www.moderntechno.de/index.php/meit/issue/view/meit19-01

- 87. Bogdan Tselen, Georgiy Ivanitsky, Anna Nedbaylo, Nataliya Radchenko. Prospects for the Use of Cavitation Mechanisms in Order to Reduce the Consumption of Natural Water in Municipal Energy. Journal of New Technologies in Environmental Science, No. 2, Vol. 6, 53–58. DOI: 10.53412/jntes-2022-2-1. URL: https://jntes.tu.kielce.pl/wp-content/uploads/2023/02/2-No-2-2022.pdf

- Obodovych Oleksandr M., Tselen Bogdan Ya., Sydorenko Vitalii V., Ivanytskyi Georgy K., Radchenko Natalia L. Application of the method of discrete-pulse energy input for water degassing in municipal and industrial boilers. Acta Periodica Technologica, 2022 (53):123-130. https://doi.org/10.2298/APT2253123O (Scopus)

- Obodovych, O., Ivanytsky, G., Tselen, B., Radchenko, N., Nedbailo, A., Shulyak, V., & Schepkin, V. (2022). Simulation of the Process of Hydrodynamic Cavitation for the Purpose of Developing Technologies for Obtaining Fuel Emulsions. Sworld-Us Conference Proceedings, 1(usc15-01), 13–16. https://doi.org/10.30888/2709-2267.2022-15-01-023

- Ivanitsky G.K., Tselen B.Ya., Radchenko N.L., Gozhenko L.P. (2022). Modeling of water hammer effect during the single cavitating bubble oscillation. // Physics of Aerodisperse Systems, № 60, 176–186. https://doi.org/10.18524/0367-1631.2022.60.267731

- Ivanitsky, G., Tselen, B., & Radchenko, N. (2022). Hydrodynamic Cavitation to Increase the Efficiency of the Lactose Crystallization Process in Milky Whey. Scientific Works, 86(1), 11 – 16. https://doi.org/10.15673/swonaft.v86i1.2396

- Obodovych O.M., Ivanytsky G.K., Tselen B.Ya., Radchenko N.L., Nedbailo A.Ye., Shulyak V.V. (2022). Mathematical Simulation of Fuels Production Processes Based on Water-Oil Emulsion by Hydrodynamic Cavitation Method. Modern Engineering and Innovative Technologies, 1(24-01), 47–55. https://doi.org/10.30890/2567-5273.2022-24-01-025

- 93. Ivanitsky G.K., Tselen B.Ya., Radchenko N.L. The prospect of using rotary-pulsation devices for processing by-products of cheese production into products for the agro-industrial complex and the food industry(2022), Problems of Environmental Biotechnology, №1, 30. https://doi.org/10.18372/2306-6407.1.17153 URL: https://jrnl.nau.edu.ua/index.php/ecobiotech/article/view/17153

Patents

- Пат. 3600 Украина 7 А23 С11/2. Спосіб виробництва замінника незбиранного молока для корму сільськогосподарських тварин. Заявка № 2003109631.Заявлено 27.10.2003; Опуб. 15.12.2004, Бюл. № 12.

- Пат. 50987 Україна, МПК (2006) A 23 C 7/00, A 01 J 11/00. Апарат вакуумної обробки молока / Долінський А. А., Шурчкова Ю. О., Гартвіг А. П., Ганзенко В.В., Маркін О.В., Дунайський В.В., Щепкін В.І., Целень Б.Я.; власник патенту Інститут технічної теплофізики НАН України. – № u201000694; заявл. 25.01.10; опубл. 25.06.10, Бюл. № 12.

- Пат. 83909 Україна, МПК (2013.01) F24F 13/00, F28D 9/00, F28F 3/08 (2006.01). Пластинчатий теплообмінник / Яроцький С.М., Целень Б.Я.; власник патенту Інститут технічної теплофізики НАН України. – № u 2013 00964; заявл. 28.01.13; опубл. 10.10.13, Бюл. № 19.

- Спосіб виробництва замінника незбираного молока для корму сільськогосподарських тварин. А.А. Долінський, Ю.О. Шурчкова, В.В. Ганзенко, Н.Л. Радченко. Патент на корисну модель А23С11/00 від 21.01.09.

- Пристрій для отримання гранульованого продукту. А.А.Долінський, Ю.О. Шурчкова, В.В. Ганзенко, Н.Л. Радченко, О.В. Маркін, В.Н. Тимченко, А.В. Пилипченко. Патент на корисну модель UА № 51042 МПК2009 В05В13/00 В01J2/16 А6 J3/00 заявл. 25.06.2010 Бюл. №12, 2010.

- Лінія отримання пастоподібного продукту. А.А.Долінський, Ю.О. Шурчкова, В.В. Ганзенко, В.В. Шуляк, О.В. Маркін, Н.Л. Радченко. Патент на корисну модель UA№55174 МПК2009 В01F7/00 B02C19/06 №201005816; Заяв. 13.05.2010, Опубл.10.12.2010 Бюл. № 23.

- Долинский А.А., Николаев Ю.Д., Бойко В.Г., Новак М А., Григоренко Г.В., Шурчкова Ю.А. Способ получения жидкого заменителя цельного молока. А.с. №1058105. – 1985.

- Долинский А.А., Шурчкова Ю.А., Николаев Ю.Д., Гартвиг А.П. Способ гомогенизации молока и устройство для его осуществления. А.с. №1780660. – 1992.

- Шурчкова Ю.О., Ганзенко В.В., Янюк Т.І., Гоженко Л.П., Маркін О.В., Шуляк В.В. Напій на основі насіння льону. Пат. України 87728, МПКА23С23/00.; Опубл. 10.02.2014. Бюл. №3/2014.

- Пат. 107042 Україна, МПК (2014.01) B05C 19/00. Пристрій для нанесення покриття на екструдат / Шурчкова Ю.О., Целень Б.Я., Дунайський В.В., Щепкін В.І.; власник патенту Інститут технічної теплофізики НАН України. – № a201307860; заявл. 20.06.2013; опубл. 10.11.2014, Бюл. № 21.

- Пат. 99823 Україна, МПК (2006.01) B06B1/10, B06B1/18, B01F7/12. Роторно-імпульсний апарат / Яроцький С.М., Целень Б.Я.; власники патенту: Яроцький С.М., Целень Б.Я. – №u 2014 14163; заявл. 30.12.14; опубл. 25.06.15, Бюл. №12.

- Patent 111624 Ukraine, A62C 31/02 (2006.01), B05B 1/26 (2006.01). Device for spraying liquid / Schepkin V.I., Tselen B. Ya., Velychko S.O., Dunaiskyi V.V.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201413696; declared 22.12.2014; published 25.11.2016, bulletin No 22/2016.

- Patent 115628 Ukraine, C02F1/20 (2006.01), C02F1/34 (2006.01), C02F 1/36 (2006.01), C02F 1/66 (2006.01), C02F 9/08 (2006.01). Device for degassing, neutralization and adjustment of physical and chemical properties of water systems / Dolinskiy A.A., Shurchkova Yu.O., Hartvih A.P., Tselen B. Ya., Konyk A.V., Radchenko N.L., Markin O.V., Shulyak V.V.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201606178; declared 07.06.2016; published 27.11.2017, bulletin No 22.

- Patent 118407 Ukraine, B01F7/28 (2006.01). Device for liquid processing / Dolinskiy A.A., Hartvih A.P., Tselen B. Ya., Konyk A.V., Radchenko N.L.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201705347; declared 31.05.2017; published 10.01.2019, bulletin No 1/2019.

- Patent 114374 Ukraine, C02F 1/66 (2006.01), C02F 1/34 (2006.01), C02F 103/02 (2006.01). Water processing method / Dolinskiy A.A., Tselen B. Ya., Hartvih A.P., Konyk A.V., Radchenko N.L.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201602746; declared 11.07.2016; published 25.05.2017, bulletin No 10/2017.

- Patent 118948 Ukraine, B01D 11/04 (2006.01). Mass exchange pulsation device for extraction and mixing / Dolinskiy A.A., Hartvih A.P., Ivanitsky G.K., Konyk A.V., Hozhenko L.P., Radchenko N.L., Tselen B. Ya.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201809825; declared 01.10.2018; published 25.03.2019, bulletin No 6/2019.

- Patent 123485 Ukraine, B01D 11/04 (2006.01), B01F 3/08 (2006.01). Mass-exchange device / Hartvih A.P., Ivanitsky G.K., Konyk A.V., Radchenko N.L., Nedbailo A.Ye., Tselen B. Ya.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201909960; declared 24.09.2019; published 24.03.2021, bulletin No 14/2021.

- Patent 124152 Ukraine, B01D 11/04 (2006.01), B01F 11/00. Pulsating cavitation device / Snezhkin Yu.F., Dolinskiy A.A., Petrova J.O., Ivanitsky G.K., Hartvih A.P., Konyk A.V., Hozhenko L.P.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201812730; declared 21.12.2018; published 28.07.2021, bulletin No 30/2021.

- Patent 124362 Ukraine, C02F 1/12 (2006.01), C02F 1/34 (2006.01), C02F 1/66 (2006.01), C02F 1/20 (2006.01). Device for degassing, neutralization and adjustment of physical and chemical properties of water systems / Hartvih A.P., Tselen B. Ya., Konyk A.V., Ivanitsky G.K., Radchenko N.L., Nedbailo A.Ye., Shulyak V.V.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201910901; declared 04.11.2019; published 01.09.2021, bulletin No 35/2021.

- Patent 125038 Ukraine, G05B 19/02 (2006.01), G05B 19/18 (2006.01), G05B 19/44 (2006.01), F15B 21/02 (2006.01). Pneumatic command apparatus / Hartvih A.P., Konyk A.V., Ivanitsky G.K., Tselen B. Ya., Radchenko N.L., Nedbailo A.Ye.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a201907100; declared 26.06.2019; published 29.12.2021, bulletin No 52/2021.

- Patent 126175 Ukraine, B01D 11/04 (2006.01). Mass exchange pulsation device for extraction and mixing / Hartvih A.P.; Tselen B. Ya.; Ivanitsky G.K.; Radchenko N.L.; Hozhenko L.P.; patent owner: Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine. – No a202006176; declared 24.09.2020; published 25.08.2022, bulletin No 34/2022.