Laboratory history

The laboratory in 2000 became part of the HMTDS department. From the beginning of the creation of the HTP department, and later the laboratory, its work was led by the laureate of the USSR State Prize, Honored Inventor of Ukraine, Candidate of Technical Sciences Leonid Grabov, who began research and development activities at the Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine in 1962. Since 2022, the laboratory is headed by Doctor of Technical Sciences Chalaev Dzhamalutdin Murshidovich.

The total number of employees in the laboratory is 10. Of these, 1 chief researcher, 2 leading researchers, 2 senior researchers, 1 junior researcher.

The degree of Doctor of Technical Sciences has 1 employee, Candidate of Technical Sciences – 4 employees.

Contacts

03164, Ukraine, Kyiv, st. acad. Bulakhovskogo, 2.

phone: +38044 409-07-68 (Chalajev D.M.),

phone: +38044 424-98-86

Email: htplab@ukr.net

Laboratory activities

The basic principles of theoretical and experimental studies of heat and mass transfer in thermal and hydrodynamic processing of complex heterogeneous systems are the creation of energy-efficient technologies and equipment for obtaining high-quality final products. The development and introduction of new technologies and equipment are based on a complex of heat and mass transfer and physicochemical processes: heat transfer during heating and cooling, phase transitions, melting, dispersion, emulsification, homogenization, mixing and dissolution, structuring, mass transfer processes, molecular diffusion and others. The laboratory’s developments are based on the use of an effective method of controlling dynamic processes – discrete-pulsed input of energy into heterogeneous systems (DPIE), which allows accumulating heat and potential energy in the working volume of the system and transforming it into kinetic energy.

The main activities of the laboratory

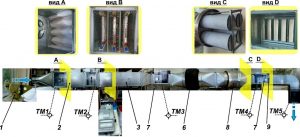

The prospects and relevance of this direction are confirmed by the proposed innovative equipment, which has a wide geography of implementation in the pharmaceutical, veterinary and food industries (pic. 1).

Teploobminnik TCG-350

Teploobminnik TO-75

Description of projects completed and in progress

1.7.1.810 “Investigation of heat and mass transfer processes for obtaining components of liquid fuels in order to create innovative technologies for the production of fuel emulsions”. (2007-2011). The key factors influencing the processes of obtaining stable emulsions from non-polar and weakly polar liquids when applying DPIE effects are determined using examples of model media, which considered liquid fuels using biocomponents, for example, fuel oil and bioethanol, with bioethanol content in a mixture of up to 30% by weight. The calorific value of traditional liquid fuels and new combined fuel emulsions was evaluated. A theoretical study of three-dimensional flow structure (velocity, pressure, energy and temperature dissipation fields) is carried out in the proposed model of rotary-pulsation apparatus of disk-cylindrical type DCT-4, in which a complex of physical manifestations of DPIE effects is realized. The research results made it possible to establish a complete hydrodynamic picture of fluid motion, and on the basis of hydrodynamic and thermophysical perturbations of flow parameters, to evaluate possible emulsification mechanisms in heterogeneous systems. Hydrodynamic treatment, at optimum temperatures of water-fuel oil emulsions, allows to obtain an energy fuel emulsion with the size of water droplets in it up to 5… 20 microns. When burning emulsions with such dispersed characteristics in furnaces, the combustion process improves and reduces the amount of harmful emissions. 1.7.1.852 “Development of methods for intensifying the processes of hydration, hydrolysis and extraction based on the use of mechanisms of discrete-pulsed energy input” (2012-2014). To intensify the extraction process, a thermal diffusion method for the extraction of biologically active substances (BAS) has been developed. The essence of the thermal diffusion extraction method is alternating filtration of the extractant through a layer of raw materials. The speed of the extractant duct is selected such as to ensure the laminar mode of extractant flow in the raw material layer. The temperature of the extractant varies in oscillating mode. Alternating filtration of raw materials with an extractant allows accelerating external mass transfer, and oscillating temperature regime of the extractant – internal. The combination of the influence of these parameters made it possible to determine the ways of intensification of mass transfer processes (maceration and extraction) in the production of galenic preparations in installations such as “Flora” and for the extraction of biologically active gases by liquefied gases in an experimental thermal diffusion plant of the “Balm” type. The results of a complex of experimental studies allowed to transfer the technology of thermocontact melting of hydrocarbon systems, which is implemented in the installation “Thermofarm-M”, which was implemented at LLC “Ternofarm” (Ukraine, industrial testing act of 09.07.2014). 1.7.1.844 “Investigation of the processes of hydrodynamics and heat and mass transfer in micro- and nanostructured dispersed media”. (together with the TGETU department) (2012-2014). The cooling properties of meso- and nanofluids obtained by DPIE, based on vegetable oils, were first investigated. Experimental studies have shown that in processes with phase transitions (boiling), the key factors of influence are not only the chemical composition of vegetable oils (dispersion medium), but also the nature, the size content of dispersed inclusions and methods for obtaining cooling media. Treatment using the DPIE method made it possible to increase the cooling capacity of vegetable oils to 1.1… 2.9 times in the range of high temperatures (600-850o C. It is shown that the qualitative difference between cooling in liquids based on rapeseed and soybean oils is the absence of the film boiling stage, which leads to an increase in the intensity of heat removal and uniformity of cooling of the sample surface in the range of high temperatures (600-850o C. 1.7.1.862 “Investigation of heat and mass transfer intensification during phase transitions and discrete-pulsed energy input in heterogeneous media by molecular and experimental modeling methods” (together with the TGETU department) (2015-2019) An experimental stand was developed and created to study the processes of impregnation of ultrafine particles into porous matrices with different structures. The use of the method of discrete pulsed energy input (DPIE) in heterogeneous systems, implemented in experimental equipment, allows creating new effective materials with high sorption capacity. The equipment is proposed and the parameters of DPIE -technology of impregnation of meso and nanosized particles into a porous adsorbent matrix are determined. The implementation of technology makes it possible to obtain a uniform distribution of dispersed particles in the matrix, thereby achieving the predictable characteristics of the functional products obtained. 1.7.1.860 “Theoretical and experimental studies of heat and mass transfer in technological processes using the method of discrete pulsed energy input” (2015-2019) Experimental models of installations based on rotary-pulsating devices such as LDTsD-750, LDTsDVM-750 and LDTsDVM-850 have been created to obtain homogeneous meso and nanodispersed systems in which the processed medium is subjected to multifactorial effects of radiation radiation and vibration. The optimal parameters that allow harmonizing the process of obtaining highly dispersed functional products are determined: circulation rate and pulsation frequency of flow, shear stress values, circumferential speed and vibration parameters when the system reaches a state of vibration boiling. The experimental device was tested in the processes of extraction of biologically active substances from the fruits of Sumy (together with NUFT specialists) and therapeutic and prophylactic agents of prolonged action (together with specialists of LLC “Kvazar Impex”). The proposed installation for obtaining nanostructured systems is effective in terms of flexibility of the technological process. The installation allows you to diversify technologies and expand the range of finished products. Program-target topics 1.7.1.712 “Investigation of heat and mass transfer in discrete-pulsed energy input into heterogeneous systems for the development of nanotechnology and their implementation” (2007-2011). A set of studies was carried out to study the physicochemical effects on the functional properties of soft dosage forms (MLF), sorption activity and kinetic stability of organosilicon nanosystems. This made it possible to offer technology for the production of nanostructured heterogeneous soft dosage forms. The development is based on the principles of directed discrete energy impact on multicomponent media, implemented in the proposed rotary-pulsating devices of disc-cylindrical type. A three-dimensional CFD-model of flow in the apparatus developed together with the Department of Modeling of Heat and Mass Transfer Processes in Energy and Heat Technologies (MPT), which allows: to identify effective zones of the apparatus by estimating the perturbation parameters of flows of fast-moving hydrodynamic processes, ways to optimize the geometric parameters of the apparatus in terms of dispersing and emulsification processes. The laboratory has developed a technical project of a new disk-cylindrical device of the DCD-4 type for implementing the principles of discrete-pulse energy input in highly dispersed systems. 1.7.1.840 “Investigation of microscale thermophysical processes in complex heterogeneous systems under the influence of mechanisms of discrete-pulsed energy input in order to develop new technologies and products” (2012-2016) The DPIE method obtained a new coolant based on geomineral water concentrate with a predominance of salts: sodium and magnesium chlorides with low corrosive effect on metals, 2-6 times lower than that of water, with a low crystallization temperature (up to -30 ºС), with a high boiling point (up to +106 ºС). A cylindrical disk-cylindrical apparatus was developed and manufactured, in which the method of discrete-pulsed energy input (DPIE) is implemented. Such an apparatus is used to obtain highly dispersed liquid systems, which include meso and nanofluids. Experimental studies have shown that the cumulative effect of hydrodynamic, hydroacoustic and hydromechanical effects in heterogeneous media is a promising method for obtaining highly dispersed systems. At the modernized stand for studying the hydrodynamic and hydroacoustic effects of DPIEs and heat and mass transfer processes in heterogeneous media, pressure ripple oscillograms for different flow modes of the model medium in a disk-cylindrical apparatus were obtained. With the help of numerical modeling, the processes of structure formation in nanofluid “silicon dioxide – distilled water” were investigated and a comparative analysis of the simulation results with an experimental sample of nanofluid obtained by the DPIE method in a rotary-pulsating disk-cylindrical apparatus was carried out. A stand for studying heat transfer processes through pipes with discrete turbulizers was developed and manufactured. Up to a hundred experimental modes have been developed, simulation of processes in pipes with discrete turbulizers has been carried out. A shell-and-tube heat exchanger with discrete turbulizers with a power of 350-400 kW was developed and manufactured, in which the heat transfer coefficients in corrugated pipes are increased by 1.5-1.6 times compared to smooth pipes. The new heat exchanger during the tests showed effective operation over the entire range of changes in thermal loads. Equipping individual heat points with a new heat exchanger will reduce the cost of their manufacture by 20-30%. 1.7.1.881 “Investigation of energy transformation processes in liquid heterogeneous systems using the method of discrete-pulsed energy input” (2017-2021). A mathematical model of heat and mass transfer in phase transition materials during heating and melting has been developed. The model allows optimizing the parameters of thermocontact melting technology with forced melt removal, which allows to reduce energy consumption and improve the quality of final products in the manufacture of medicines (drugs), such as ointments, suppositories. According to the results of experimental and laboratory studies, the principles of creating a regulated dynamic state of highly concentrated solid-liquid systems under the complex influence of hydrodynamic and hydroacoustic effects have been developed. The dominant factors influencing the dispersion and structural homogeneity of ultrafine systems in heterogeneous processes of material technologies are determined. The laboratory offers heat and mass exchange equipment for a full cycle of production of soft dosage forms: thermocontact technology for the preparation of ointment bases and DPIE -technology of dispersion and homogenization in heterogeneous systems. 1.7.1.887 “Scientific principles of improving the energy efficiency of heat technologies for the production of alternative fuels” (2018-2019). For transesterification, a method of discrete-pulsed energy input (DPIE) implemented in a rotary-pulsating apparatus is proposed, This allows to reduce the required operating temperature of the process and ensure a continuous mode of operation of production equipment due to intensification. Experimental dependences of the degree of biofuel yield on the process temperature, equipment performance, operating mode of the rotary-pulsating apparatus and the ratio of initial products were obtained. Experimental thermotechnological parameters of the process of transesterification of vegetable oils with methyl alcohol have been determined to ensure a continuous mode of operation of the stand for testing modes for obtaining biofuels. The use of a heat pump for distillation of excess alcohol and heat recovery can save 60… 80% of thermal energy, which is spent on heating the original products in the process of obtaining diesel biofuels. Practical recommendations for the implementation of energy-efficient technology of continuous production of diesel biofuels have been developed. Agreement No 34 “Development of thermopulsation technology and experimental plant for obtaining liquid biofuels for the needs of municipal and industrial energy” (program “Biomass as a fuel raw material (BIOFUEL)” (2007-2009) . The development of heat and mass transfer processes of the technology for obtaining liquid biofuels for the needs of municipal and industrial energy on laboratory and bench equipment was carried out. The thermophysical parameters of processing processes in the manufacture of liquid biofuels based on vegetable oils and alcohols are determined. Based on the performance of heat and mass transfer studies and modeling of hydrodynamic processes in apparatus for energy input into heterogeneous systems, a thermopulsation technology for obtaining liquid biofuels is proposed. Agreement No 29 “Intensification of heat and mass transfer processes for obtaining liquid biofuel mixtures by the method of directed discrete energy impact” (program “Biomass as a fuel raw material (BIOFUEL)”) (2010-2012). A study of heat and mass transfer processes for obtaining liquid biofuel mixtures using the principles of discrete-pulsed energy input on laboratory and bench equipment was carried out. The thermophysical parameters of processing processes in the manufacture of liquid biofuel mixtures are determined. The modes of obtaining liquid motor and energy fuels with biocomponents are investigated. The calorific value of biofuels (bioethanol and biodiesel) and their mixtures with traditional fuels has been experimentally measured. The generalization of research results is carried out. According to the research results, an innovative technology for the production of biofuel mixtures using the principles of discrete pulsed energy input (DPIE) to accelerate mass transfer and thermophysical processes is proposed. Technical documentation for scientific and technical products “Station for preparation of biofuel mixtures SPBS-1000”, with a capacity of 1000 l / h, has been developed. The developed equipment uses the principle of DPIE to intensify the heat and mass transfer processes for the preparation of biofuel mixtures. Agreement No. 22 “Development of innovative technology and continuous installation using a reactor with discrete turbulizers for the production of liquid biofuels” (program “Biological resources and new technologies of bioenergy conversion”) (2013-2017). A new experimental rotary-pulsation apparatus LDTSD-750 was developed and manufactured, designed for homogenization of emulsions, as well as for intensification of physicochemical processes in the manufacture of liquid biofuels. A new experimental stand for the study of heat technology processes for the production of liquid motor biofuels was created. The experimental modes of operation of bench equipment for the study of heat and mass transfer processes for the production of liquid biofuels were carried out. Experimental studies were carried out to determine the thermokinetic regularities of the process of transesterification of vegetable oils with methyl alcohol using alkaline catalysts. The influence of various factors on the kinetics of the process (the influence of temperature, the ratio of the starting products and the catalyst, the influence of the intensity of hydrodynamic processing of the reaction mixture) was experimentally determined. The results of experimental studies will be used to find methods to intensify the processes of obtaining liquid biofuels and energy-saving methods of bioenergy conversion of raw materials and the development on their basis of a pilot plant for the production of liquid biofuels. Joint scientific and innovative projects, economic contracts Agreement No 34 “Development of thermopulsation technology and experimental plant for obtaining liquid biofuels for the needs of municipal and industrial energy”, program “Biomass as a fuel raw material (BIOFUEL)” (2007-2009) The development of heat and mass transfer processes of the technology for obtaining liquid biofuels for the needs of municipal and industrial energy on laboratory and bench equipment was carried out. The thermophysical parameters of processing processes in the manufacture of liquid biofuels based on vegetable oils and alcohols are determined. Based on the performance of heat and mass transfer studies and modeling of hydrodynamic processes in apparatus for energy input into heterogeneous systems, a thermopulsation technology for obtaining liquid biofuels is proposed. Agreement No 29 “Intensification of heat and mass transfer processes for obtaining liquid biofuel mixtures by the method of directed discrete energy exposure” (program “Biomass as a fuel raw material (BIOFUEL)” (2010-2012) A study of heat and mass transfer processes for obtaining liquid biofuel mixtures using the principles of discrete-pulsed energy input on laboratory and bench equipment was carried out. The thermophysical parameters of processing processes in the manufacture of liquid biofuel mixtures are determined. The modes of obtaining liquid motor and energy fuels with biocomponents are investigated. The calorific value of biofuels (bioethanol and biodiesel) and their mixtures with traditional fuels has been experimentally measured. The generalization of research results is carried out. According to the research results, an innovative technology for the production of biofuel mixtures using the principles of discrete pulsed energy input (DPIE) to accelerate mass transfer and thermophysical processes is proposed. Technical documentation for scientific and technical products “Station for preparation of biofuel mixtures SPBS-1000”, with a capacity of 1000 l / h, has been developed. The developed equipment uses the principle of DPIE to intensify the heat and mass transfer processes for the preparation of biofuel mixtures. Agreement No. 04-08-12 “Investigation of compatible processes of heat and mass transfer in multicomponent systems for the development of sorption converters of heat of a new generation” (NAS of Ukraine and Siberian Branch of the Russian Academy of Sciences, 2012-2013). Analytical and experimental study of heat and mass transfer in sorption thermotransformer devices was carried out. Laboratory tests of experimental samples of adsorbers on new sorption materials created in the IR SV of the Russian Academy of Sciences. Based on the analysis of the efficiency of the use of energy resources in industry, the temperature potential of heat of various devices generating thermal energy, the parameters of the duty cycles of sorption thermotransformers are determined and the initial data for the synthesis of energy-efficient adsorbents for sorption heat converters are given. The obtained data are the basis for the development of an adsorption heat converter of a new generation, the creation of which will contribute to increasing the efficiency of energy resources use and attracting secondary and renewable energy sources to energy circulation. The existing models of sorption heat converters (SHC) are studied, and the concept and hardware design of the new generation adsorption unit are developed. An experimental SPT sample was manufactured, its bench tests were carried out and the energy indicators of the actual adsorption cycle were studied. Based on the results of generalization of experimental data, recommendations for the use of SHC in industry and agro-industrial complex are developed, initial data for the calculation and design of SHC are formulated. Technological schemes for connecting heat / cooling systems have been developed. Agreement No3259 dated 18.10.2013 “Installation for heating and melting viscous and low-thermal conductive substances “Termobat-M” (LLC “Ternofarm”, industrial test report dated 09.07.2014. ). The installation implements a thermocontact method of heating and melting hydrocarbon systems with an improved unit for forced melt removal. Agreement No1 dated 10.10.2016 “Investigation of structural formation processes in obtaining new forms of medicinal and prophylactic agents” (KVAZAR IMPEX LLC, 2016-2017). Within the framework of the agreement, the influence of the physicochemical nature of the dispersed phase and its optimal concentrations in the medium of a highly mineralized solution and a mixture of water-alcohol plant extracts on the processes of structure formation are determined. To obtain structured application tools, a schematic diagram, technology and small-sized installation for its implementation are proposed. The conducted studies have shown that the structured form is a new class of composite therapeutic and prophylactic agents with improved properties: prolonged action; sedimentation stable system in which activity lasts longer; uniform volume density of distribution of dispersed particles, which affects the quality and release of active components. Contract Р 5.10.1 “Development of recommendations for the calculation, design and application of geothermal energy supply systems in public utilities and agro-industrial complex” (target research program of the NAS of Ukraine “Reliability and durability of materials, structures, equipment and structures (Resource-2)” (2017-2018). Circuit solutions for geothermal heat supply systems using previously drilled re-equipped wells of the Hadiach geothermal field have been developed. Improved methods for extracting geothermal energy using borehole heat exchangers in oil and gas fields with low flow rate of thermal waters have been proposed. A methodology for calculating the processes of thermal and moisture treatment of coolant in drying plants has been developed and equipment for drying agricultural products using low-temperature geothermal energy has been proposed. Contract Р 5.8 “Extending the life of drying equipment by improving heat generating systems” (target research program of the NAS of Ukraine “Reliability and durability of materials, structures, equipment and structures (Resource-2)” (together with the HMTHT department, 2016-2020. ) The choice of a constructive solution is substantiated and design documentation for a heat-generating heat pump unit is developed. A prototype of a heat pump unit for a chamber-type convective dryer was manufactured. According to the test results, the design documentation was adjusted. The obtained actual energy indicators of the heat pump unit confirmed the preliminary calculations and amounted to 0.5-0.9 kWh per kg of evaporated moisture. The act of acceptance of a prototype of a heat pump unit was received. Agreement No. 2002 “Determination of technological parameters for obtaining rheologically complex suspensions on a hydrophobic basis” (KVAZAR IMPEX LLC, 2020). The influence of temperature parameters, concentration of the dispersed phase and shear stresses on the fluidity of the system “nanoscale silicon dioxin-hydrophobic base” is determined. The technological modes of processing and the experimental batch of hydrophobic greases have been developed. Contract No. 2785 “Heat Engineering Audit of Convective Drying Unit SP-730” (jointly with TMPT Department, 2020). The process of dehydration was studied and the analysis of thermal conditions during dewatering of raw material was carried out. The kinetics of moisture exchange depending on the process parameters are investigated. Recommendations on intensification of drying process and reduction of energy costs in SP-730 drying unit have been issued. Agreement No. 1019 “Development of application technology technology” (KVAZAR IMPEX LLC, implementation acts No. 1 dated 30.11. No. 2 dated 28.10.2021). The technology was developed and a pilot-industrial installation for obtaining nanostructured forms of prophylactic and therapeutic agents based on a wide range of plant extracts was proposed. A modification of the disk-cylindrical apparatus of the DCD-4 type for the implementation and intensification of heat and mass transfer processes in the proposed technology has been developed. Agreement No. 1–06/20 dated 17.06.2020 “Routine maintenance before commissioning of the installation for the implementation of physicochemical processes in dispersed systems” (LLC “Pharmamedica”, implementation acts No. 1 dated 30.11.2020, No. 2 dated 28.10.2021). Within the framework of the contract, a set of works was performed to test the functional operability of the nodes and the stability of the installation systems. Testing the efficiency of functional units was carried out on test media: dispersion of hydrophobic silicon dioxide in water. According to the results of the work, the hydrodynamics in the product circuit, the operating parameters of dispersing and homogenization in suspension forms were optimized, design changes were made to the disc-cylindrical apparatus of the AP-1000 type. 8,60.63 (8,60/63) Development of equipment for air disinfection in air conditioning systems of public buildings by photocatalysis and plasma chemistry in the context of the COVID-19 pandemic (jointly with the EEZ named after E.O. Paton of the National Academy of Sciences of Ukraine, 2021) . Specialists EEZ them. E.O. Paton of the NAS of Ukraine together with specialists of the IET of the NAS of Ukraine developed and created equipment for cleaning aerodisperse flows by the method of exposure to low-temperature plasma of atmospheric pressure. High cleaning efficiency is achieved by creating an increased concentration of ozone in the ionization chamber, which increases the number of active radicals in the air and intensifies the destruction of molecular pollutants, inactivation of pathogenic microorganisms, etc. The authors have developed a technological scheme and modules for the installation of plasma-chemical air purification in the supply and exhaust ventilation systems of buildings with a module of combined (catalytic-thermal) method of ozone excess destruction. Test tests of the effectiveness of air disinfection were conducted on experimental equipment. Contract Р 5.5 “Extension of the service life of previously drilled mothballed wells by methods of geothermal technologies for the generation of heat and electricity (target research program of the NAS of Ukraine “Reliability and durability of materials, structures, equipment and structures (Resource-2)” (2016-2018). A method of thermal calculation of three-generation geothermal installations based on sorption heat pumps for use at objects of the agro-industrial complex has been developed. Technological schemes for increasing the temperature potential of a geothermal energy source with the help of ab- and adsorption heat pumps are proposed, optimal operating modes of sorption heat pumps are calculated and their energy indicators are determined under conditions of variable temperatures of the heating source.

Commercial offers of the GTP laboratory

The laboratory is open to all forms of cooperation wit for developing and manufacture scientific and technical products is created as a result of the research. The scientific and technical products are integrated in the pharmaceutical and processing enterprises in Ukraine and abroad. Samples of the developed equipment are presented on the site: http//www.htplab.kiev.ua. We are interested in joint development and implementation of projects in the following areas: The obtained research results of scientific works: – “Development of accelerated heat technology and equipment for the production of soft dosage forms in the pharmaceutical industry and pharmacies.” – “Creation of resource-saving technology and a range of hygrothermal equipment for the dehydration of thermolabile substances in pharmacy and processing industry.” – “Research of the processes of energy input in the system “solid-liquid”. Scientific, technical and technological developments are carried out for the production of new forms and types of products of various industries: – medical, pharmaceutical, chemical and microbiological preparations; – natural plant extracts, phytopreparations and biologically active products; – soluble and structured proteins, feed and food products of vegetable (animal) origin; – new class of coolants; – efficient tube-based heat exchangers with discrete vortex turbulators.

Main publications of the laboratory

Monographs:

Patents: