ANALYSIS OF HEAT AND MASS TRANSFER PROCESSES AND COATINGS LIFE TIME FOR EQUIPMENT HIGH TEMPERATURE PARTS OF THERMAL POWER PLANTS FOR SUPERCRITICAL STEAM PARAMETERS

The use of protective coatings parts steam turbine plants (STP), working at very high temperatures, allow the use of heat strength properties of ferritic – martensitic steels. The transition temperatures of steam to 650 ° C and higher will improve the efficiency of STP to 50% and thus reduce fuel consumption by 10 … 12% and emissions up to 10% compared to current turbine. The blades life time resourse characterize the protective functions of coating material to be protected under specific conditions, flow diffusion and oxidation.

Problem. The need to obtain a numerical value life time prediction metal coatings, it is possible on the basis of long-term prediction of mass transfer processes in detail-coating system.

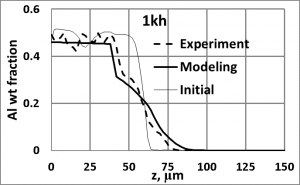

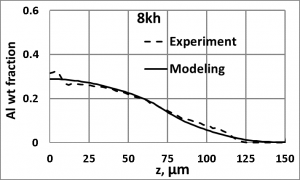

Proposition solutions. Based on the developed models of diffusion processes for determining life time recourse coatings components and turbine blades of new power plants for supercritical steam parameters. Simulation is carried out with the help of mathematical models that take into account the diffusion processes of formation and growth of the oxide film, phase transformations, as well as deformation and destruction of coating. The created model of diffusion and corrosion processes in the system of protective coating-substrate in conjunction with the settlement and experimental approach allows you to define life time under consideration coating (Fig. 1).

|

|

(a) (b)

Figure 1. Comparison of the concentration profiles obtained in the simulation (bold curves) and experimental (dashed curves) for exposures 1- (a), 2 – (b) for thousands of hours.

Newness. Be created a more accurate mathematical models of heat and mass transfer processes and a special computer program based on them. They make it possible to predict and evaluate warranty period STP blades.

Publications:

- Krukovskyi, M.Metel, A.Aguero, R.Muelas, V.Kolarik, Diffusion and lifetime modeling for slurry aluminide coating on P92 substrate at 650° C with a computation-experimental approach, Mater. Corr., 2015 (is in print).

- Pedraza, M.Proy, C.Boulesteix, P.Krukovskyi, M.Metel, Slurry aluminizing of IN-800HT austenitic stainless steel and pure nickel. Correlations between experimental results and modelling of diffusion, Mater. Corr., 2015 (is in print).