ANALYSIS AND FORECASTING OF RESOURCE AND AVERAGE TEMPERATURES OF PROTECTIVE COATINGS OF GAS TURBINE BLADES

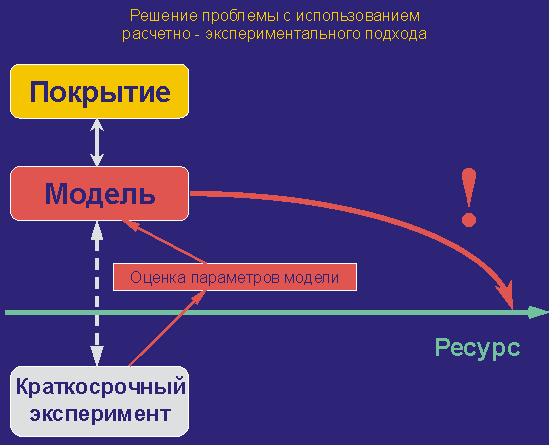

Problem. The service life of metal coatings of the MСrAlY type determines the service life of gas turbine blades. Since the service life of coatings should be tens and hundreds of thousands of hours, therefore, full-scale experimental studies are very long and expensive. Calculation methods make it possible to predict the service life of a coating based on short-term experimental studies (up to several thousand hours).

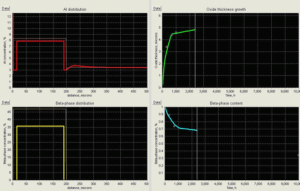

Suggestion for solving the problem. The laboratory has developed the following models of physical and chemical processes (diffusion and corrosion), as well as estimates of the average temperatures of the protective coatings of GTE blades (Fig. a). For this, a computational-experimental approach is used based on a model of the main physical and chemical processes that determine the life of the coating by identifying the parameters of the model according to the experimental study (Fig. a).

|

|

|

а

This approach and model are implemented in the COLTAN (Coating Life Time Analysis) program, which makes it possible to analyze the oxidative and diffusion processes in the coating, which determine the service life of the coating according to the criterion for the end of aluminum in the coating.

On fig. Figure 2 shows fragments of the interface of the COLTAN program when calculating the concentration profiles of different aluminum phases over time (Fig. b).

b

Commercial offer.

The developed computational and experimental approach and models of physical and chemical processes in the protective coatings of GTE blades can be used to calculate the working life of various types of coatings.

The work was carried out and financed by:

- Mashproekt, (Mykolaiv, Ukraine) – Creation of calculation methods for heat diffusion characteristics and work resource of multi-layer protective coated blades of gas turbines (1993-1997).

- Implementation of the International NATO Science for Peace Project 972631 – Life time modeling for MCrAlY coatings for industrial gas turbine blades (1999-2003).

- Ministry of Education and Science of Ukraine – Development of a method of forecasting the service life of protective coatings of gas turbine blades (2000-2001).

- Institute of Chemical Technologies (Germany) for the research of coatings used by the company “EdF” (Electricity de France) (France) – Life time prediction by inverse problem solution for an MCrAlY coating used by Electricite de France (2001 – 2002).

- The company SIEMENS AG, Power Generation (Germany) – MCrAlY coating life time analysis with COLTAN software and SICOAT data (2003-2004).

Publications:

- L. В. Getsov, P. G. Krukovski, N .V. Mozaiskaja, Aleksander I. Rybnikov, K. A. TadljaA NEW METHOD FOR DETERMINING THE REMAINING LIFETIME OF COATED GAS-TURBINE BLADES // Materials and technology 2011, V.45, N 1, pp. 21–26.

- Krukovsky P., Kolarik V., Tadlya K., Rybnikov A., Kryukov I., Juez-Lorenzo M. Theoretical and experimental approach for long term modelling of oxidation and diffusion processes in MCrAly coatings – Proc. of EFC Workshop “Lifetime Modelling of High Corrosion Processes”, 2001, №34, p. 231-245

- Krukovsky P., Tadlya K., Rybnikov A., Kryukov I., Mogaiskaya N., Kolarik V., Juez-Lorenzo M. Combined experimental and theoretical approach for long time high temperature oxidation and diffusion processes in MCrAlY coatings investigation. – Proceedings of the VIII seminar “Diffusion and thermodynamics of materials”. Brno, 2002 pp 176-179