1. Heating hot water fire and water tube boiler KVVD-0,63 Gn

|

| Nominal heating efficiency, MW | 0,63 |

| Adjustment range, % | 40-100 |

| Efficiency , %, not less (actually to nominal load – 93 %, to 50 % – 95%) | 92 |

| Discharge intensity of fuel, nm3/MW , not more | 115,5 |

| Boiler exit water temperature oС | 95 |

| Overall dimensions, mm,

length with the burner width height |

3260 900 1600 |

|

Boiler mass, kg, not more |

1700 |

2. Heating hot water -tube boiler KVN-1,0 Gn

|

| Nominal heating efficiency, MW | 1,0 |

| Adjustment range, % | 40 – 100 |

| Efficiency , %, not (actually to nominal load – 93 %, to 50 % – 95%) | 92 |

| Discharge intensity of fuel, m3/MW , not more | 122 |

| Boiler exit water temperature, 0С | 95 |

| Overall dimensions, mm,

length with the burner widt height |

2800 1150 2017 |

| Boiler mass with the burner, kg | 1870 |

3. Heating hot water-tube boiler KVN-2,0 Gn

|

|

Nominal heating efficiency, MW |

2,0 |

|

Adjustment range, % |

40 – 100 |

|

Efficiency , %, not (actually to nominal load – 93 %, to 50 % – 95%) |

92 |

|

Discharge intensity of fuel, m3/MW , not more |

110 |

|

Boiler exit water temperature, 0С |

95 |

|

Overall dimensions, mm, length with the burner width height |

4000 1500 3000 |

|

Boiler mass with the burner, kg |

3700 |

Implementation of the boiler let to replace outdated boilers “Minsk 1”, “NIISTU-5”, “Universal”, “Energy” etc., two times increase heating capacity of the boiler houses without changing their total structural volumes, to increase deeply their efficiency and reliability of heat supply sources.

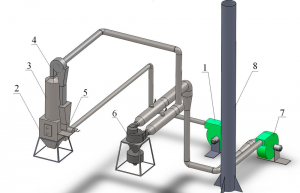

4. The stand No 1 for investigating the efficiency of burning low-grade fuel in the combustion chamber with low-temperature fluidized bed gas cleaning systems of ash and sulfur oxides.

|

|

| 1. scavenger fan VVD No 5;

2.combustor boiler LTFB; 3. heat exchanger; 4. dual channel Centrifugal Filter; 5. auger fuel; 6. two-level six-channel centrifugal filter CF2-6-06; 7. exhauster; 8. smokestack. |

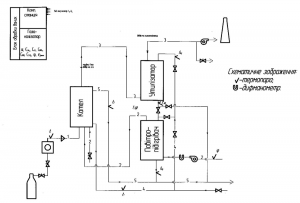

5. The stand No 2 for the research of burning pallets, solid waste, coal, timber, to study the efficiency of contact heat recovery heat exchanger with different materials heat transfer surfaces, research methods reduce the generation and purification of toxic flue gases

|

|

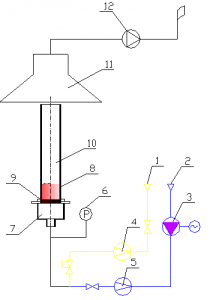

6. The stand No3. The laboratory setup for investigating the characteristics of the liquefied bed

|

|

| 1 – gas supply (propane-butane);

2 – blast air for liquefy; 3 – The fan with the regulation of feeding; 4 – a device for measuring the gas flow rate; 5 – instrumentation tor measure the combustion air; 6 – a device for measuring the air pressure (gas mixture) on entering the air separation grating; 7 – mixing chamber; 8 – liquefied layer; 9 – discharge grille; 10 – quartz chamber; 11 – vent umbrella; 12 – exhaust fan |

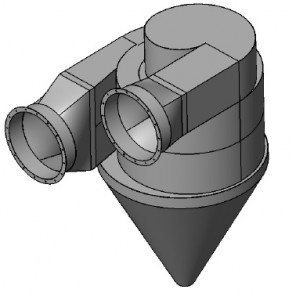

7. For reducing emission of ash in the atmosphere from the solid fuel boilers proposed and tested on a number of productions by our experts dusting apparatus “centrifugal filter” that combines centrifugal separation and filtration of dusty stream.

The number of chambers of separation and channels therein may vary depending on the specific production conditions (gas flow rate, the particulate composition of dust, the desired degree of purification, etc.).

|

|

|

Overall types of centrifugal filters

8. Heatrecovery

|

9. Regional program for the modernization of municipal power system of Ukraine

10. Methodological support for industry programs to reduce greenhouse gas emissions