Description completed and implementation projects

DEVELOPMENT OF THE EQUIPMENT FOR EFFICIENCY OF FUEL COMBUSTION IN BOILERS UP TO 3.5 MW DEPENDING ON THE GAS QUALITY USING α-PROBE

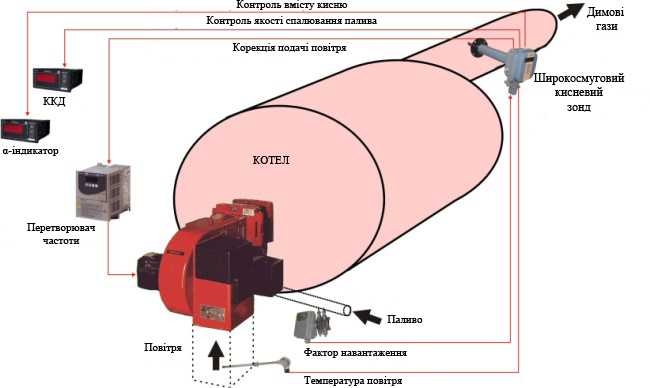

The goal of the work – the development of equipment to improve the efficiency of fuel combustion in boilers up to 3.5 MW depending on gas quality using α-probes, which provide low-toxic combustion of natural gas with a low nitrogen oxide emissions.

The results of the research. Finished the development and research of equipment to improve the efficiency of fuel combustion in boilers up to 3.5 MW with using α-probes. At the first time provides full automation of the boiler using a wideband oxygen sensor to ensure continuous operation of boiler energy saving by adjusting the air supply to the furnace, depending on the oxygen content in the flue gases.

Introduction the “air-gas” ratio control system with automatically adjusts speed of air fan in operating area boiler allowed for low emissions combustion of natural gas in particular, to reduce nitrogen oxide emissions by 20-30%, and carbon monoxide – 4-10 %. In this case the natural gas consumption was reduced by 8-15%, electricity – 20%. In addition, automatic adjustment of the burner operating modes provides a high level of safety and reduce noise during operation of the thermal unit.

The novelty of the development is confirmed by 3 patents of Ukraine.

AUTOMATED CONTROL STATION OF HEAT CONSUMPTION

Intended for working as an individual substation in residential, office and industrial buildings.

Automated control station of heat consumption is used as a permanent experimental-industrial test bench.

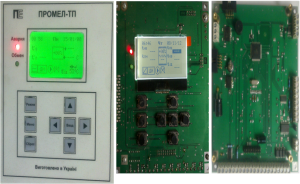

Main Specifications: thermal power – 0.3-1.0 Gcal; control range of coolant temperature – 30-90 C; automatic maintenance of comfortable temperature in the room, automatic maintenance of comfortable temperature in the room.

Development features: optimization of thermal modes and control algorithms, which provided the original electronic control unit.

Advantages:

- provides weather-dependent regulation of the flow temperature in heating systems in accordance with a heating schedule;

- provides heat curve correction, depending on the time of day, day of week, etc.;

- provides for the protection of the internal heating system from exceeding the external pressure;

- works efficiently in heating systems with one pipe and two pipe wiring;

- available in 2 versions: block-modular or individual performance;

- 90% used domestic components.

Trial operation of the automated control room heat consumption showed that in residential buildings, energy savings can be up to 15-20%; administrative and industrial – 20-35%.

The payback period ‒ 2 years.

DEVELOPMENT AND IMPLEMENTATION OF AUTOMATED HEAT CONTROL STATION OF HEAT CONSUMPTION WITH SOLAR COLLECTORS AND ACCUMULATORS OF HEAT

|

|

The goal of the work – the creation of the current installation of an automated heat control station with heat consumption (ASHC) with solar collectors and a heat accumulator and recommendations for the use of combined heat circuits with alternative sources of heat energy corresponding to the controls and their operation algorithms.

Results. On the basis of the use of solar collectors and heat the battery, optimization of thermal modes and control algorithms that are provided with the original electronic controller, developed ASHC installed on the 7-th building of Institute of Engineering Thermophysics of NASU. Energy savings achieved by automatically regulating the flow temperature in dependence on the solar activity, outside temperature, time of day, day of week, decrease of temperature in the room in the absence of humans. Trial operation ASHC on 7-th building with area 4.400 m2 showed that reached thermal energy savings of up to 40%.

DEVELOPMENT OF TECHNOLOGY AND POWER TECHNOLOGY PLANT FOR THE TREATMENT OF BIOMASS

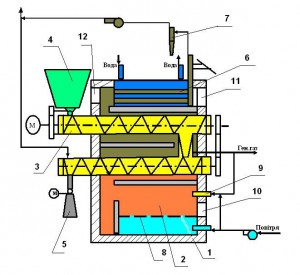

The goal of the work – to provide a method for treatment of biomass and the creation of the plant for producing combustible gas and biocarbon for various applications (fuel, sorbent, fertilizer carburizer).

Results. The initial biomass undergoes thermochemical processing to produce a fuel gas and biocarbon. The next materials can be used: wood and its waste, and biomass of agricultural production (straw, stalks, husks of sunflower, buckwheat, rice, etc.). The process is  performed by pyrolysis in the movable layer sandwiched with outer and inner heat of the combustion process heating fuel.

performed by pyrolysis in the movable layer sandwiched with outer and inner heat of the combustion process heating fuel.

The installation can produce a combustible gas, biocarbon and the heat carrier (hot water or air).

Developed energy-technological treatment of biomass technology is protected by two patents of Ukraine.