DEPARTMENT OF HEAT AND MASS TRANSFER IN HEAT TECHNOLOGIES (HMTHT)

History of the Department

In order to carry out scientific research to develop energy-efficient heat technologies and equipment for processing plant raw materials into dried and powdered products, the department of heat technologies for food powder production was established in 1988. In 2002, the department was reorganized into the department of non-stationary heat and mass transfer in drying processes in connection with the expansion of scientific topics. In 2017, the department was renamed the scientific department of heat and mass transfer in heat technologies (HMTHT). In order to improve the structure of the Institute in 2018, the HMTHT department was merged with the department of heat and mass transfer processes and equipment. At present, the department is called the department of heat and mass transfer in heat technologies.

In order to carry out scientific research to develop energy-efficient heat technologies and equipment for processing plant raw materials into dried and powdered products, the department of heat technologies for food powder production was established in 1988. In 2002, the department was reorganized into the department of non-stationary heat and mass transfer in drying processes in connection with the expansion of scientific topics. In 2017, the department was renamed the scientific department of heat and mass transfer in heat technologies (HMTHT). In order to improve the structure of the Institute in 2018, the HMTHT department was merged with the department of heat and mass transfer processes and equipment. At present, the department is called the department of heat and mass transfer in heat technologies.

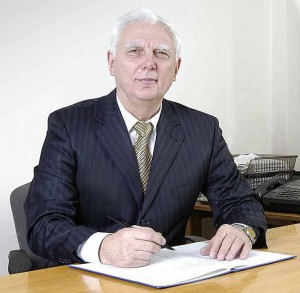

The department is headed by Yury F. Snezhkin – head of the Institute, doctor of technical sciences, professor, academician of the National Academy of Sciences of Ukraine, laureate of state prizes of the USSR and Ukraine, laureate of prize named after academician A.V. Lykov NAS of Belarus. Snezhkin Y.F. is the author of more than 750 scientific publications, including 18 monographs and more than 155 inventions and patents.

Contacts:

e-mail: ittf_ntps@ukr.net

03057 Kyiv, Marii Kapnist st. 2а

tel:+38 (044) 456-62-82 – reception;

03164 Kyiv, Academician Bulakhovsky st. 2

tel: +38 (044) 424-20-26 – reception;

tel/fax: +38 (044) 424-15-26 – Snezhkin Y.F.

The main directions of scientific activities of the HMTHT department

– study of kinetics of convective drying of colloidal capillary-porous materials in order to intensify external heat and mass exchange and internal heat and mass transfer by experimental and analytical methods; – intensification of heat and mass exchange processes in the production of composite materials, including based on peat in order to improve the quality of peat fuel; – creation of energy-saving heat-technologies and equipment for processing vegetable raw materials into dried products and powders; – research of energy saving methods in heat engineering processes with the use of sorption and compression heat pumps; – development of the theory of interconnected processes of heat and mass transfer, diffusion, filtration, evaporation and deformation during dehydration of colloidal capillary-porous materials; – development and implementation of energy-saving heat-technologies, equipment and regulatory and technical documentation; – intensification of technologies for the production of basalt fibers and products based on them; – replacement of natural gas with solid fuel.

Detailed directions of activities of the HMTHT department

ENERGY EFFICIENT HEAT TECHNOLOGIES Development of the theory of interconnected processes of heat and mass transfer, diffusion, filtration, evaporation and deformation during dehydration of colloidal capillary-porous materials; determination of thermophysical and chemical properties of colloidal capillary-porous materials and powdered products; carrying out analytical, physical and chemical control of materials in the process of their technological processing; study of the kinetics of drying processes of colloidal capillary-porous materials in order to intensify external heat and mass exchange and internal heat and mass transfer. The following projects were completed within the direction: – development of heat technologies and equipment for the production of functional food powders from plant materials; – introduction of technology and technological line of LP-40 brand for the production of apple powder at the Belorechensk cannery of the Krasnodar territory. The line was handed over to the Interdepartmental Admission Commission of the Ministry of Mechanical Engineering for the Light and Food Industries and Household Appliances of the USSR, was rated “highest quality category”, recommended for serial production (1982); – introduction of technology and technological line of LPP brand for production of powders from apples and vegetables in the research shop of Salivonkivsky sugar factory in Kyiv region. The line was successfully handed over to the Interdepartmental Admission Commission of the State Agrarian Industry of the USSR, recommended for serial production (1988); – introduction of technology for the production of low-calorie beet pulp powder in the research shop of the Salivonkivsky sugar factory in Kyiv region, which was adopted by the Interdepartmental Admission Commission of the State Agrarian Industry of the USSR, recommended for serial production (1993); – introduction of convective heat pump drying units for low-temperature drying of thermolabile materials in a closed circulation circuit at enterprises of various forms of ownership in Ukraine; – introduction of more than 60 technological lines for processing plant materials into food powders, including in Slovakia, Vietnam and CIS countries; – a license was sold and a contract was signed for technology and equipment for the production of apple pomace powder, which was successfully implemented in Czechoslovakia at the Frucona plant in Sabinov; – in the framework of cooperation with Vietnam, heat technology for processing tropical crops into food powders has been developed. Two joint Vietnamese-Ukrainian enterprises “Dokifa” and “Tienki” for the production of food powders from bananas and pineapples were established, which allowed to produce natural food powders for the first time in the conditions of high humid tropical climate (2000); – development and research and industrial implementation of innovative resource-saving environmentally friendly heat technology to obtain new forms of dried health products in the form of fruit and vegetable chips; – development of waste-free energy-efficient heat technology and industrial-technological line for obtaining seeds of grain, oil and vegetable crops using heat pumps. Energy consumption is reduced by 40% of the normative energy consumption for seed grain, and material germination at the level of 98-100%. Technical Specifications developed and approved by Ukrmetrteststandart: TU U 88.066.001-1998 «Soy and vegetable concentrates»; TU U 88.066.012-2000 «Instant pumpkin porridge»; TU U 88.066.013-2000 «Dyes food natural red from beets»; TU U 88.066.014-2000 «Instant jelly»; TU U 88.066.015-2000 «Natural carotene paste»; TU U 88.066.019-2001 «Apple powder»; TU U 15.3-05417118.024-2002 «Vegetable powders»; TU U 15.3-05417118-037:2009 «Dried fruits and persimmon food powder»; TU U 15.3-05417118-038:2010 «Dried watermelon»; TU U 10.3-05417118-045:2012 «Antioxidant powders from vegetable raw materials»; TU U 10.3-05417118-046:2012 «Folate-containing powders from vegetable raw materials»; TU U 10.3-05417118-047:2012 «Phytoestrogenic powders from vegetable raw materials»; TU U 10.3-05417118-048:2012 «Prebiotic powders from vegetable raw materials»; TU U 10.8-39289268-001:2014 «Fast food products from natural products. Lunch dishes»; TU U 10.3-05417118–053: 2016 “Fruit and vegetable chips” (from apricots, plums, pineapples, quinces, bananas, pears, peaches, plums, persimmons, apples, beets, pumpkins, zucchini, carrots, white roots, and assorted of fruit or vegetables at least two types of ingredients in any combination). According to the results of scientific developments on the creation of new waste-free resource-saving technologies and their implementation, state awards of the USSR and Ukraine were received (1984, 2006). RENEWABLE ENERGY SOURCES Research of heat and mass transfer processes in the production of composite biofuels based on peat and plant biomass in order to improve its quality indicators. The following projects were implemented within the research: – development of the innovative technology for processing peat to fertilizers and fuel, which is protected by patents of Ukraine for inventions: № 116663 and № 117651. Patent license for the technology was sold to the Socialist Republic of Vietnam (2018). – development of the new technology for production of composite fuel briquettes and pellets. Creation of technology for pressing briquettes and pellets with reduced pressure (up to 10 MPa ) with preliminary thermoplasticization by thermo-moisture treatment of raw materials. The Technological Instructions for production and Technical Specifications were approved for peat fuel pellets with adding sawdust, sunflower husks, with 1.5…2 times lower ash content and 20% higher the calorific value in comparison with peat briquettes. Technical Specifications developed and approved by Ukrmetrteststandart: TU U 10.3-05417118-36:2005 “Peat fuel pellets” TU U 02.2-05417118-051:2015 “Granulated fuel from peat, plant raw materials and their mixtures”. TU U 02.2-05417118-051:2016 “Heat-treated granulated fuel from peat, plant raw materials and their mixtures”. TU U 02.2-05417118-056:2019 “Granulated and briquetted fuel from mixtures of chemically activated peat and plant raw materials”. The invention “Method of obtaining high-calorie biofuels” (Patent for invention UA 116663 C2; the inventors: Snezhkin Y.F., Korinchuk D.M., Bezgin M.M.) won the All-Ukrainian competition “Invention of the Year 2020” in the category: “Energy and energy efficiency”. ENERGY SAVING Research of energy saving methods in thermal engineering processes with the use of renewable and alternative energy sources, heat pumps; creation of waste-free resource-saving technologies of the production of dried to equilibrium humidity and powdered materials. The following projects were completed within the direction: – development for the implementation of DSTU 8304:2015 Energy conservation. Energy cost of the technological process of district heating. Methods of determination. Kyiv, 2017. (authors O. Buninа, N. Dabizha, T. Korinchevska, P. Rosen, Y. Snezhkin, D. Chalaev, V. Shavrin). – development of technological scheme and design estimates for the installation of heat pump hot water heating capacity of 1.4 MW in Kramatorsk, Donetsk region. The installation was introduced in 2009 in two districts of the city and saves 1.5 million m3 of gas annually. (The work was performed under the direction of the Design Bureau of Institute). ENERGY EFFICIENT EQUIPMENT Development of energy efficient technologies and regulatory and technical documentation for the production of alternative and renewable fuels and food products; creation of theoretical foundations for the development of heat pumps and heat storage units. The following projects were completed within the direction: – development for the implementation of DSTU 8305:2015. Energy conservation. Energy cost of the process of services on district hot water supply. Methods of determination. Kyiv, 2017. (authors O. Buninа, N. Dabizha, T. Korinchevska, P. Rosen, Y. Snezhkin, D. Chalaev, V. Shavrin). – tunnel and belt drying plants, a heat pump drying plant, a technological line for processing bananas and pineapples in Vietnam have been developed and introduced. To carry out fundamental and applied research, the department is equipped with experimental stands, installations and equipment:

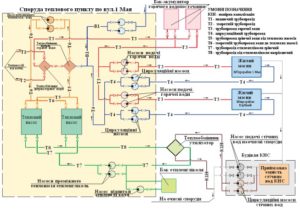

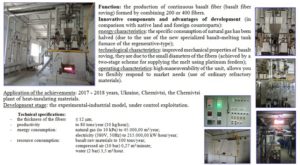

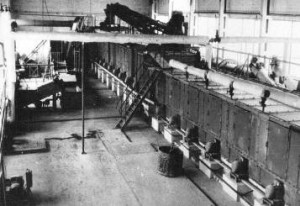

Description of ongoing and completed projects of the HMTHT department

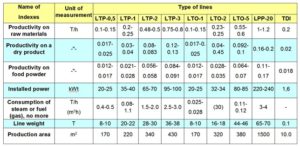

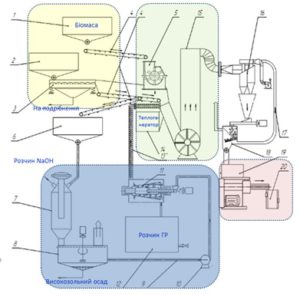

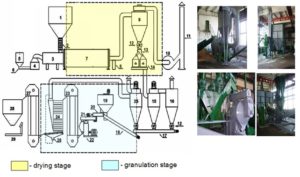

Tunnel dryers TF4, SZR, TF2 90…550 kg/h 800…1100 kg/h Heat pump drying unit Productivity on evaporated moisture: 4,2…5 kg/h Technological line Heat generator to the drying installation working with the use of the heat pump Area of loading of raw materials and unloading of dried material Technological lines with tunnel and belt dryers Technical characteristics of technological lines with the use of tunnel and belt drying units with a capacity of 0,1 to 1,2 t/h for vegetable raw materials with possible sources of heat carrier by steam, liquid fuel, gas or biomass. Drum dryer for drying mineral fertilizers In the calculation of the process of dehydration of mineral fertilizers in the drum dryer, the thermal power and parameters of the source of the drying agent are determined, the technological scheme of the drying process is created. According to the technological scheme, the selected equipment is a drum dryer and a drying agent removal system, the general layout of the equipment is made. As a source of drying agent used a heatgenerator that runs on wood fuel. The Heatgenerator on fuel of vegetable origin The heatgenerator running on wood fuel (cod and granules) and is able to stagnation ments a big piece fuel (wood, etc.). Process burning fuel two-stage – a clamped layer and a jet stream mode ignition; has high environmental friendliness. It has no analogues. The heatgenerator is made of three units: a combustion and mixing unit (furnace) and two remelters with a thermal capacity of 350 kW each. The remelters, due to the peculiarities of their work, include: bunkers for small fuel (chips and pellets), storage of small fuel, loading device of large fuel and combustion devices of the clamped layer. Implemented: 1) in the process of drying mineral fertilizers in a drum dryeras the source of the drying agent, the company of “ORIY” LLC thermal capacity is 0,7 MW (Ukraine, Berezan); 2) in the technological process of drying sand in a drum dryer at the enterprise LLC “VKP” Notes”, has a thermal capacity of 0,3 MW (Ukraine, Sumy) Solid propellant burner of the clamped layer Designed for the solid alternative fuel combustion: different grades of coal, waste processing of agricultural products, timber industry and small fuel – pellets and briquettes. Can be used ground for the creation of boilers and heating equipment and boilers furnaces for conversion dryers, operating on natural gas, with a view to substituting alternative fuels. The advantages The effectiveness Burner device can be made on the heat output depending on the customer’s needs, respectively fuel used. Burner device The burner device is designed to work on boilers and heat generators. The burner burns: small fractional solid fuel – various coal, industrial waste and processing of agricultural products (buckwheat husk, oats, millet, rice, husks, sunflower, peanuts, pistachios, chaff, sawdust, etc. ); liquid fuel – from light to fuel oil and water fuel emulsions (including from man-made hydrocarbons ); gaseous – natural and industrial gases. Burning fuel is in ignition mode, which provided heating fuel to ignition temperature by high-temperature combustion products of additional fuel: liquid or gaseous. Consumption of additional fuel about 1 – 6% of the total fuel consumption in the burner the appliance first, depending on the type of fuel. Technical characteristics: Completeness of fuel combustion – up to 1.0. Thermal capacity – from 0,8 to 10 MW. When working on natural gas allows to obtain in the exhaust gases the content of carbomonoxide – 0,0025 – 0,0075%, nitrogen oxides 127 – 140 mg/m3. Burner device for combustion the solid fuel of agricultural products and natural gases Technology of peat and biomass processing to composite fuel For the first time in the world the technology for processing peat to fertilizers and fuel was developed (Patents of Ukraine for inventions: № 116663 and № 117651). Patent license for the technology was sold to the Socialist Republic of Vietnam. The technology for producing composite biofuels involves integrating the technology of humic substances extraction from peat in the production cycle of a peat briquette plant. The removed humus component is compensated by the introduction up to 40% of plant biomass to the fuel. – composite fuel peat briquettes; – solution of sodium humate with up to 10% dry matter Thermal characteristics of composite briquette: pressure for pressing 20 – 40 MPa; humidity 12%; peat component 60%; the content of the residue after extraction 30%; flexural strength 5.5 MPa; ash content 10%; calorific value 17 MJ/kg. Technologies for producing the granular composite fuel 1 – bunker; 2, 6, 17, 18– conveyer; 3 – mixer; 4 – combustion chamber; 5 – bunker of heat generator; 7 – drum dryer; 9, 25 – cyclone; 10 – smoke exhauster; 11 – smokestack; 12 – sluice; 13 – flow distributor; 14 – hammer crusher; 15,16 – cyclone; 19 – bunker of granulator; 20 – screw feeder; 21 – moistener; 22 – press – granulator, 23, 27 – noria; 24 – cooling column; 26 – separator; 28 – bunker for products; 29 – scales. Technical Specifications of Ukraine: TU U 10.3-05417118-36:2005 “Peat fuel pellets” TU U 02.2-05417118-051:2015 “Granulated fuel from peat, plant raw materials and their mixtures”. TU U 02.2-05417118-051:2016 “Heat-treated granulated fuel from peat, plant raw materials and their mixtures”. TU U 02.2-05417118 – 056:2019 “Granulated and briquetted fuel from mixtures of chemically activated peat and plant raw materials”. Calorific value is up to 5300 kcal/kg Density is up to 1300 kg/cubic meter Attrition strength is up to 98,5% Technology is implemented at “Vista-Dnipro” Ltd., Kovel, “Nasha energija” Ltd., Sosnytsia Technologies for heat and cold supply of industrial and municipal enterprises based on sorption and vapor compression heat pumps that utilize heat from low-grade and alternative energy sources Connected load of hot water supply Q = 1,24 Gkal/h Number of consumers – 4401 peopl. The source of low – potential heat is sewage water Heat pumps – 2 ps.; Type – Carrier 30HXC 080-375 COP – up to 3,6 The modular unit for the production of continuous basalt fiber The experimental-industrial model of the new energy-efficient unit for the production of the continuous basalt fiber is created and put into exploitation (together with the Chernivtsi plant of heat-insulating materials). Dry ration of hot food for servicemen Special dry rations of hot food have been developed to supply the Armed Forces of Ukraine. Dry rations of hot food consist of natural food powders without chemical impurities, obtained by convective drying and contain vitamins, macro- and microelements, enzymes, that increase their biological value and have pronounced functional (antioxidant, folate, prebiotic and phytoestrogenic) properties, normalize metabolism and enhance the protective functions of the body. These products are used to prepare first, second and third lunch dishes: soups, mashed potatoes and vegetables, porridge, meat products, jelly, desserts and more. They are pre-prepared (with all the flavors) powdered compact mixtures with a long shelf life. The cooking time of such products is 3-5 minutes, which is especially important in extreme situations. When recovering (adding boiling water to the dry mixture), the volume increases 7-8 times. Recommended for both individual and catering. Determination of chemical composition and quality control of native raw materials and final products is carried out in the physico-chemical laboratory of the department. Individual ration per day, with an energy value of 3600-3800 kcal (kcal can be increased or decreased depending on needs) and weighing from 400 to 935 g (weight and configuration of special dry rations depends on individual needs, tasks and duration of time of their execution) was developed. If necessary, it is possible to quickly organize the production of instant products in the required quantity. The actual of the technology was covered in the domestic media; products are presented at international exhibitions in Ukraine. The rations were tested by soldiers of the 72nd mechanized and 95th airmobile brigades, who praised the quality and nutrition of the dishes offered to them. The rations were presented to the President of Ukraine and the General Staff of The first instant dishes are borsch with meat. Resource-saving environmentally safe technology production of fruit and vegetable chips Fruit and vegetable chips – a new natural dessert product recommended by experts for health and dietary nutrition. By their structure, they are crispy plates, dried to low residual moisture with a pronounced natural taste and color inherent in the raw material. Special distinction of fruit and vegetable chips is: The technology of production of fruit and vegetable chips is based on the method of convective drying of pre-prepared raw materials in multi-stage dehydration, which reduces energy consumption during production by up to 20% and reduces costs by up to 15%. In contrast to world developments, the technology provides for the production of natural chips without artificial preservatives and fillers with the maximum degree of preservation of the natural phytocomplex of raw materials, the recoverability of which is 25…30% higher than existing analogues. The technology is protected by 10 patents of Ukraine, developed technological instructions for production and approved by Ukrmetrteststandart TU U 10.3-05417118-053:2016 “Fruit and vegetable chips”. Financial support for the widespread introduction of technology and the establishment of domestic industrial production will increase domestic competitive natural environmentally friendly fruit and vegetable chips for sale in national and international markets. Daily consumption of chips satisfies the body’s needs for natural vitamins, trace elements and other vital substances that are in a balanced and harmonious combination. Chips from apples, carrots, persimmons

Belt dryers AGSO, SLR

Productivity on evaporated moisture:

Productivity on evaporated moisture:

for processing bananas and pineapples into dried products in Vietnam

The main technical reference.

for combustion of solid, liquid and gaseous fuels

by thermochemical method

Burner device for combustion the water fuel emulsions and natural gases

with extraction of humic substances

Products:

the Armed Forces of Ukraine at the armored range and also received a positive assessment. Their high quality was confirmed on January 31, 2015 by the statement of the spokesman of ATO A. Lysenko at a briefing on television. The relevance of the main areas of work is covered in the media, in particular Forbes magazine №8: “How can Ukraine provide the army with “space food”; in the newspaper “Svit” №45-46 (December 2014) “Ukrainian cyborgs thank scientists for innovative borscht!”; in the magazine “Viche” №1, (January 2015) “Innovative dry rations”; in the newspaper “Governmental Courier” (January 16, 2015) “Lunch for the Cyborg”. The series of programs “Golden Stock of Ukraine” on the BTB channel shows an interview with the main developers of rations, which has a high rating. This development took the first place among the highlighted scientific works for the Armed Forces of Ukraine on the BTB channel in the series “Golden Reserve of Ukraine”.

the Armed Forces of Ukraine at the armored range and also received a positive assessment. Their high quality was confirmed on January 31, 2015 by the statement of the spokesman of ATO A. Lysenko at a briefing on television. The relevance of the main areas of work is covered in the media, in particular Forbes magazine №8: “How can Ukraine provide the army with “space food”; in the newspaper “Svit” №45-46 (December 2014) “Ukrainian cyborgs thank scientists for innovative borscht!”; in the magazine “Viche” №1, (January 2015) “Innovative dry rations”; in the newspaper “Governmental Courier” (January 16, 2015) “Lunch for the Cyborg”. The series of programs “Golden Stock of Ukraine” on the BTB channel shows an interview with the main developers of rations, which has a high rating. This development took the first place among the highlighted scientific works for the Armed Forces of Ukraine on the BTB channel in the series “Golden Reserve of Ukraine”.

Presentation of dry rations to the President of Ukraine and the General Staff of the Armed Forces of Ukraine at the armored range

Main publications of the HMTHT department

Scientists of the department have published more than 800 scientific papers, including more than 180 certificates of authorship and patents. Monographs Articles in foreign journals Articles Patents

Information about the main employees of the HMTHT department

Petrova Zhanna Oleksandrivna is a chief researcher, head of the laboratory of heat and mass transfer processes in heat technologies of the HMTHT department, in 2005 she defended her PhD thesis, in 2013 – her doctoral dissertation; in 2007 she was awarded the title of senior researcher. Scientific activity is aimed at creating, research, development of modern energy-saving equipment and heat technologies of new types of dry plant powders and fast food products based on them, biofuels and peat-based fertilizers, improvement of modern methods of analysis to determine basic thermophysical and physicochemical indicators of colloidal capillary-porous materials in the dried and powdered state in the development of technological processes of their production. Member of the Academic Council of the Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine; Scientific Secretary and Member of the Specialized Academic Council for the Defense of the Scientific Degree of Doctor (Candidate) of Technical Sciences at the Institute of Technical Thermophysics of the National Academy of Sciences of Ukraine (D 26.224.01); member of the editorial board of the magazines “Ceramics: Science and Life” and “Sofia Prima: Dialogue of Eternal Return”; 2014-2015 – Secretary of the section of light and food industry of the Committee on State Prizes of Ukraine in the field of science and technology with the right to vote; member of the specialized academic council for the defense of the degree of doctor (candidate) of technical sciences at the National Technical University of Ukraine “Kyiv Polytechnic Institute. I. Sikorsky”. About the high level of scientific results of Petrova Zh.O. testifies to the award of the title “Inventor of 2016 of the National Academy of Sciences of Ukraine”, the award from the National Academy of Sciences of Ukraine “For professional achievements of the NAS of Ukraine”. Received an international award in the competition of innovative applied technologies for the presented innovative project: “Innovative heat technologies for the production of functional products”, Weihai, China, 2018. Awarded a commemorative award for scientific achievements in honor of the 100th anniversary of the National Academy of Sciences of Ukraine from the Presidium of the National Academy of Sciences of Ukraine. In 2019 she was elected a full member (academician) of the Ukrainian Academy of Sciences in the field of technical sciences. In the same year she was awarded a diploma of a participant of the International Academic Forum “Scientific and Technological Innovations and Cooperation” on behalf of the Secretary General of the Forum, Beijing, China. The most significant scientific achievements: – developed and implemented working methods for determining the chemical composition of food powders (carotenoids, dietary fiber, fiber, etc.); – for the first time developed and obtained a patent for an express method for the determination of pectin substances; – for the first time developed modern energy-efficient innovative heat technologies for obtaining functional powders; – created antioxidant, phytoestrogenic, folate-containing, prebiotic compositions from plant raw materials that have health-improving properties; – developed energy-efficient methods of preview preparation of functional raw materials; – the influence of parameters of convective drying of seeds of grain, oil, vegetable and technical cultures on intensity of their dehydration and germination is experimentally established and substantiated; – obtained a decrease in the heat of evaporation of water from functional raw materials by increasing the permeability of cell membranes; – the optimum temperature of dehydration of betanin-containing raw materials at which preservation of betanin is maximum is established; – the dependence of the yield and degree of destruction of cells of highly dispersed antioxidant, phytoestrogenic, folate-containing and prebiotic powders on the rotation speed of the grinder rotor and the separation time of the dried crushed functional raw material was obtained; – determined equilibrium humidity and optimal storage conditions for antioxidant, phytoestrogenic, folate-containing, prebiotic powders, which allowed to reduce by 2 times the loss of quality of these powders during their long-term storage; – functional fast food products were developed for the first time; – the classification of the received functional powders is developed; – for the first time the actual data of specific heat of evaporation of phytoestrogenic plant mixture are established; – it is established that in the process of dehydration of phytoestrogenic plant mixture there is a reaction of soybean fats with fat-soluble carotenoids, which affected the specific heat of evaporation of water from the material; – the parameters of the dehydration regime are set for the maximum preservation of biologically active substances of the phytoestrogenic mixture; – numerical modeling of heat and mass transfer during convective drying of antioxidant and phytoestrogenic raw materials was performed and graphs of dependences were obtained; – for the first time the stage of extraction of humic components from peat was integrated into peat processing production, which allowed to remove up to 20% of humic substances for production of highly efficient fertilizer; – developed energy-efficient waste-free heat technologies and equipment for processing vegetable crops to obtain seeds and food powder. Co-author of 5 monographs, has 45 patents, 16 technical conditions and more than 182 scientific publications. Bileka Borys Dmytrovych is a leading researcher, in 1971 he defended his dissertation, in 1980 he was awarded the title of Senior Research Scientist, in 1996 he defended his doctoral dissertation, in 1986 he won the State Prize of Ukraine in science and technology. From 2004 to 2011 he was the head of the department of technologies of combined energy production of IET of NAS of Ukraine. During the period of work at the Institute scientific activity is connected with development of methods of thermal and hydraulic calculation of cooling systems of high-temperature engines and their experimental proof, creation of methods of thermal calculation and development of technologies of energy utilization of high-temperature waste heat of engines with using low-boiling working bodies, development of scientific bases and practical methods of introduction of cogeneration and combined power plants for municipal heat power and heat technologies. Recently, the activity is aimed at creating methods of thermal calculation and analysis in the development of combined cogeneration and heat pumping technologies for municipal heat and heat technologies. The most significant scientific achievements: – for the first time in the USSR as part of the co-authors developed and published guidelines for the principles and practical methods of calculation and research of air cooling systems for high-temperature engines for stationary and transport purposes; – unique experimental researches of thermal state of full-scale engines and temperature and hydraulic characteristics of their cooling systems are carried out. As a result, systems and methods for their calculation have been improved, which has increased the efficiency and reliability of engines for energy, gas transportation, aviation and the navy. The results of the work were awarded the State Prize of Ukraine; – for the first time in Ukraine and the CIS the idea was offered and the technique of thermal calculation of power cycles of power plants is created. Power plants utilize high-temperature waste heat of engines with low-boiling working fluids of saturated hydrocarbons. Technological schemes of such plants with high energy efficiency and prospects of use at compressor stations of the main gas pipelines are developed. – methodical provisions of introduction of cogeneration and combined cogeneration-heat pump units in municipal heat power engineering of Ukraine are developed. On their basis projects of modernization of municipal heat power engineering of a number of areas of Ukraine were executed, the basic types of thermal schemes of such installations, ways of increase of their economy and environmental friendliness were developed; – mathematical models and methods of comparative analysis of fuel efficiency of combined energy production with traditional thermal energy technologies are developed. It was recommended for the choice of power equipment in design developments, as well as in the analysis of the efficiency of work of various types of units, including variable modes of operation. He has more than 150 scientific publications, including about 40 certificates of authorship and patents of Ukraine and the USSR, co-author of 6 monographs. Paziuk Vadym Mykhailovych is a leading researcher of the HMTHT department, in 2011 he defended his PhD thesis, in 2014 he was awarded the title of associate professor, in 2019 he defended his doctoral dissertation. The direction of scientific activity is directed on research: heat-exchange processes of capillary-porous materials, in particular drying of seed and food grain; creation of functional food powders; development and implementation of heat-pump technologies and equipment in the drying process, as well as waste-free technologies for processing vegetable crops to obtain quality seeds and food vegetable powders. The most significant scientific achievements: – for the first time the influence of low-temperature drying regimes on the qualitative characteristics of seed material with the construction of drying kinetics curves is scientifically substantiated; – the developed a mathematical model of the drying process of cereals and derived regression equations with the construction of response surfaces from the multifactorial effect on the drying time, germination and heating temperature of seeds; – for the first time the theoretical calculation of kinetics of drying of seeds of grain, oil and vegetable cultures with definition of the generalized characteristics of kinetics of process is carried out; – heat and mass transfer characteristics at low-temperature drying of seed materials were studied for the first time; – developed energy-efficient low-temperature step modes with low moisture content of the coolant with the study of drying kinetics of seeds of cereals, oilseeds, vegetables and laboratory analysis of material germination after drying; – designed and manufactured drying units with a heat pump for drying seed crops; – new resource-energy-saving heat technologies for obtaining seed crops have been developed. He co-authored more than 80 scientific publications, including 3 monographs, 9 patents and 4 technical conditions, and has 5 publications in foreign journals in scientometric databases Scopus, Web of Science. Mykhailyk Vyacheslav Avramovich is a leading researcher, head of the laboratory of physicochemical and thermophysical research of the HMTHT department, in 1981 he defended his dissertation; in 1990 he was awarded the title of senior researcher, specialty thermophysics and molecular physics. Scientific activity is aimed at studying the methods of thermochemical analysis (DSC, Calve calorimetry, evaporation calorimetry, TG and DTA) of thermophysical and physicochemical properties of colloidal capillary-porous materials and their changes in technological processes; the state of water in biological objects during drying and storage; processes of thermal decomposition of components and compositions of solid fuels based on vegetable raw materials and peat in order to improve existing and develop new energy- and resource-saving technologies for fuels. The most significant scientific achievements: – for the first time in the world experimental practice in a Calve-type calorimeter in a wide range of temperatures and supersaturation of solutions on single crystals the heat of crystallization of sucrose and its temperature dependence was investigated and determined; – hydration of carbohydrates was studied by DSC method, dependences of the degree of hydration of sucrose, glucose, fructose and sorbitol on concentration were obtained for the first time. They became the basis for understanding the dependences of bound water content and heat of vaporization on the moisture content of sugar-containing raw materials during drying; – as a result of studying the state of water in plant materials by the DSC method in the process of drying and long-term storage, a decrease in the specific content of bound water in the presence of free water was detected for the first time. Theoretical substantiation of the experimental fact is given; – studies of the specific heat of dehydration of plant sugar-containing materials and sugar solutions for the first time experimentally established that its excess over the specific heat of evaporation from the surface of pure water depends on the energy of interaction of water with sugars and biopolymers; – the method of research of specific heat capacity of damp materials by DSC method as a result of which values of specific heat capacity of apples and sugar beet are received is offered. For the first time in the world analytical equations of their dependences in wide intervals of temperatures and humidity are constructed; – for the first time by the method of thermochemical analysis it is shown that increasing the drying temperature of sugar-containing raw materials due to changes in the speed of drying and crystallization leads to a decrease in the degree of crystallinity of the dry product and an increase in amorphous phases; – for the first time a complex study of thermophysical properties of natural and Na-modified montmorillonite clay of Cherkasy deposit was performed. Data on their heat capacity, thermal conductivity, water condition, drying kinetics and equilibrium humidity are obtained. They became the basis for the design and construction of an experimental shop for the production of bentonite clay powders in the Dashukov section of the field; – a comprehensive experimental study of thermophysical properties, performance characteristics and kinetics of heat storage by materials with a phase change based on organic compounds was performed. According to the results of the performed researches the design of the heat accumulator is developed and the candidate’s dissertation is defended; – using the developed methods of thermochemical analysis, studies of the processes of thermal decomposition of a wide range of plant and animal biomass, peat, brown coal, household and industrial waste in the dispersed and granular state. The obtained results became the basis for the creation of technologies for the production of composite solid fuels and humus fertilizers from peat. Co-author of 2 monographs, has 29 copyright certificates and patents, as well as 252 scientific publications (including 47 in foreign journals). Google Shcolar citation statistics – 232, h-index – 9, 10-index – 8. Under the scientific guidance of Mikhailik V.A. 2 candidate dissertations were defended. Shapar Raisa Oleksiivna is a leading researcher, head of the Energy saving laboratory in the drying process of the HMTHT department, in 2004 she defended her PhD thesis, in 2006 – was awarded the title of senior researcher. Scientific activity is directed on theoretical and experimental researches on studying of the mechanism of heat and moisture transfer, generalization of kinetic laws during drying of colloidal capillary-porous materials, establishment and substantiation of ways of intensification and increase of efficiency of heat and mass transfer processes, improvement of existing and creation using traditional and renewable heat sources. The most significant scientific achievements: – for the first time in the world as part of the scientific team of the department developed resource-saving heat technology for processing fruits and vegetables and their pomace into natural dried products, with low residual moisture ≤ 8%, which is much lower than the equilibrium with the environment and powdered products; – for the first time proved and confirmed by the patent of Ukraine, the feasibility of thermoplasticization of dried plant materials to avoid thermoplasticity during dispersion and fractionation, energy-saving process parameters are determined providing an increase in the yield of the fine fraction (particle size less than 250 μm) to 65…70% with minimal energy consumption; – the optimum quantitative ratios of initial components, conditions of restoration and introduction of fruit and vegetable powders to foodstuff are defined and protected by patents of Ukraine; – thermophysical, structural-mechanical and technological properties of tropical crops (bananas, pineapples) as objects of drying are studied, the influence of heat-moisture parameters of drying agent on kinetic regularities of convective drying is investigated, on the basis of which natural food powders from bananas and pineapples, introduced at the enterprises of Vietnam “Dokifa” and “Tienki”; – on the basis of a joint analysis of the kinetics of moisture and heat transfer, based on the nature of the change in the numerical value of Rebinder, as a criterion for optimization, substantiated multi-stage drying regimes of plant thermolabile materials, including seed crops and soybean-vegetable mixtures according to which the temperature of the material during dehydration does not exceed the maximum allowable value, a high degree of preservation of natural components of raw materials and intensification of the process; – the first time in Ukraine developed resource-saving ecologically safe technology of new dried health foods as fruit and vegetable chips, based on the method of high-speed convection drying the pretreated feedstock modes multistage dewatering, which will reduce energy costs up to 20% reduction in the cost of chips 15%. Innovative heat technology is confirmed by 10 patents of Ukraine and technical specifications; – studies of low-temperature dehydration of energy willow in the technological cycle of solid biofuel production determine the rational conditions of the process and the parameters of the drying agent, ensuring the efficiency of drying and obtaining the final material with low and evenly distributed residual moisture. She has more than 220 scientific publications, including 26 copyright certificates and patents, co-author of 3 monographs and 9 technical conditions of Ukraine for new products and materials. Korinchuk Dmytro Mykolayovych is a leading researcher and head of the laboratory of thermophysical processes of biofuel production of the HMTHT department. In 2010 he defended his thesis and obtained the PhD degree; in 2013 he obtained the senior researcher degree. His scientific activity is devoted to: the study of thermophysical, physicochemical, structural and mechanical properties of biomass and peat; heat and mass transfer processes of raw material preparation; drying of biomass and peat, as well as the development of innovative methods of granulation of biofuels based on peat and plant biomass; energy efficient technologies for the production of solid composite biofuels from agrobiomass mixtures of different origins and different stages of physicochemical and thermophysical processing; scientific principles of energy efficiency improvement and complex resource saving in heat technologies for the production of alternative fuels. The most significant achievements: – for the first time in Ukraine and the CIS: it was proposed to consider the compressed biofuel as a composite biopolymer with a non-oriented structure; the feasibility of using compositions in the production of compressed fuel was substantiated, that leaded to a new innovative approach to the production of fuel pellets; – for the first time in Ukraine: the composition of granules and briquettes based on peat and plant biomass, using peat as a binder and biomass as a reinforcing frame, was developed; the optimal composition for the production of high-calorie biofuels was determined; – for the first time in international practice: the mathematical model for high-temperature drying polyfractional composite mixtures was developed; the combined scheme for drying biomass in the aerodynamic multi-section dryers, as well as combination of the drying process and mechanical activation in dryers were substantiated; the energy efficient drum dryer with dynamic adjustment of angle of inclination was developed. Innovative drying technologies ensure a 20% reduction in energy consumption for the drying process and the minimal moisture difference of raw materials – fractional homogeneity in moisture content. Project “Drying complex SK-3 for wood, grass, agricultural waste” was awarded the diploma of the finalist of the VII festival of innovative projects “Sikorskiy challenge 2018”. – directions of increasing the calorific value of biofuels was investigated and for the first time in the world the energy-saving modes for production of high-calorie heat-treated composite biofuel from compositions of plant biomass and peat was substantiated. These modes ensure increase of calorific value by 15-30% and energy-efficient granulation. The patent for the invention “Method of obtaining high-calorie biofuels” (116663) was recognized as the winner in the nomination “Energy and energy efficiency” at the All- Ukrainian competition “Invention of the Year 2020”. – for the first time in the world: methodological principles of non-isothermal analysis of fuel pellets were developed. This allowed identifying and investigating methods for peat and biomass activation before granulation, determining physicochemical mechanisms of ligament formation in pellets under mechanical and thermal activation. – for the first time in the world: the physico-chemical model of energy-efficient pelletizing plant biopolymers was developed and substantiated. It results in activating lignin complex due to combination of modes of mechanical activation and thermo-moisture treatment of raw materials. The method ensures the sustainable biofuel production and reducing energy for pressing almost 4 times. The project “Technology of production of surface-glazed pellets with increased caloric content and strength, that are stable during storage and transportation” was awarded the diploma of the finalist of the VII festival of innovative projects “Sikorskiy challenge 2018”. – scientific principles for technology of chemical activation of peat were developed. The use of activated peat component as a natural binder in composite peat-biomass granules, that reduces the energy for pressing almost 1.4 times, and as highly effective fertilizer for restoring the humus layer of soils was substantiated. The study was the basis for the creation of innovative resource-saving technology for complex processing of peat to composite fuel and humic fertilizer, by which up to 20% of weight of dry peat processed into humic fertilizer. The residue of peat after extraction is used in composite fuel as a binder. At the initiative of Korinchuk D. and with his direct participation, six new resource-saving technologies for the production of composite fuel briquettes and pellets were developed and implemented, as well as the technology of complex peat processing into fuel and fertilizer. Three Technical Specifications were approved for them. These technologies are included in the catalog of advanced developments of NAS of Ukraine. He has 166 published scientific papers in the field of production of alternative fuel, including 2 in English-language journals; citation statistics Google Shcolar -– 69, h-index – 4, and 10-index – 1; he is the co-author of 12 patents. As part of the international transfer of technologies of processing peat for fuel and fertilizer, the ITTF NASU sold abroad (Vietnam) two patents in 2018-2019. Ulanov Mikhail Mykolayovych is a senior researcher, head of laboratory of energy efficiency of thermal transformation processes of the HMTHT department; in 2003 defended his thesis and obtained the PhD degree. Scientific activity is aimed at developing energy-efficient and energy-saving technologies for various industries and housing and communal services based on the use of heat pumps. The most significant results: – for the first time in Ukraine, a heat pump unit with a heat output of 1.45 MW was developed and implemented in 2008; the heat pump unit utilizes the heat of untreated sewage for the purposes of hot water supply of 4.5 k pers., which living in two districts of Kramatorsk, Donetsk region; – in 2014, a heat pump unit with a heat output of 14 kW was developed and implemented; it utilizes the heat of water of the river Desna for hot water supply and space heating of the Theoretical School of Advanced Training of Researchers of IET of NAS of Ukraine, which is located in the village Sokolivka, Chernihiv region; – the design documentation of a typical heat-generating unit with a heat output of 250 kW was developed, which utilizes the heat of the mine waters for the purpose of hot water supply to order of the Ministry of Energy of Ukraine. He has 6 patents and more than 110 scientific publications. Kremnev Vyacheslav Olegovich is a head of the laboratory of heat and mass transfer processes and devises of the HMTHT department; awarded two Gold medals of the Exhibition of Achievements of the National Economy of the USSR; Laureate of the State Prize of Ukraine for 1998 in the field of science and technology for the creation and implementation of energy-saving technologies and equipment based on the principle of discrete-pulse energy input. Scientific activity is aimed at the intensification of heat technology processes (drying, concentration, hygrothermal treatment, homogenization, emulsification, sterilization, high-temperature heat treatment). Created technological plants are implemented at more than 150 enterprises in 6 industries of Ukraine and abroad, according to the conclusions of interdepartmental admission commissions, including international ones, a number of developments exceeded the technical level of industrialized countries. The most important completed and implemented innovative developments: – technology and equipment for obtaining fuel water-oil emulsion; – technology and equipment for production and application of bitumen-polymer water-emulsion waterproofing mastics; – technology and equipment for dispersion and homogenization of a wide range of emulsions and suspensions; – technology and equipment for the production of concentrated tomato products using the homogenization of tomato mass; – technology and equipment for homogenization of canned baby food; – technology and unit for heat treatment, homogenization and deaeration of pureed baby food; – technology and equipment for the production of high-quality grape juice materials; – technology of mayonnaise production using rotor-pulse homogenizers; – technology and equipment for obtaining flax fiber by thermobiological method; – technological complex of tobacco extract concentration, drying, and technological conditioning of recombinant tobacco. In recent years, developed and implemented, with the definition of basic technical and economic indicators, in terms of long-term controlled operation: – the prototype model of the tank furnace of the recuperative type for basalt smelting brand PPB-1RC; – the prototype model of the tank furnace of the regenerative type for basalt smelting brand PPB-2RG; – experimental-industrial model of the new energy-efficient unit for the production of basalt super thin fiber (BSTF) by duplex technology; – modernized conveyor plant for drying of flat semi-rigid heat-insulating products on the basis of BSTF; – modernized tunnel plant of convective drying of discrete-continuous action; – the prototype model of the new energy-efficient modular unit for the production of basalt continuous fiber (basalt roving); – innovative technological line for the production of fire-resistant composite panels. There are 45 copyright certificates and patents and more than 100 scientific publications. Abarzhi Ivan Ivanovich is the leading researcher in the laboratory of heat and mass transfer processes and devises of the HMTHT department. He has received his PhD Degree in Physics and Mathematics in 1980, and his Doctor of Sciences Degree in Engineering Physics in 2004. He has been awarded the Degree of Senior Scientist in the National Academy of Sciences of Ukraine in 2006. Research and key professional achievements of I.I. Abarzhi are in theoretical analysis in the area of heat and mass transfer in complex poly-disperse media. These problems have a broad range of industrial applications in, e.g., textile materials processing. Particularly, in collaboration with Dr Malkin, I. Abarzhi has developed the theory of transport processes in materials with bi-porous structures. The model accurately captured the effects of the input resistance and the non-isothermal adsorption kinetics which are known to play an important role in realistic environments and which are challenging to account for. The important professional achievement of I.I. Abarzhi is the theory of heat and mass transfer in heterogeneous systems under conditions of local thermodynamics non-equilibrium. This theory identified the essentially wave character of transfer process in non-equilibrium conditions and directly linked the wave transport and the transition between the wave and diffusion transports to control parameters the system. The results of these theoretical studies have important practical outcomes. They have been applied, for instance, in high-temperature energy-saving technologies of the processing of textile materials and in the development of industrial equipment for their implementation, and have proven to be efficiency. Some particular technological applications of theoretical analyses of I.I. Abarzhi include the stabilization and fixation of dyes in textile materials in extreme environments involving the super-heated steam, the high-speed convective-radiation, the air temperatures exceeding the temperature of the material destruction, and the processing of textile materials by foamed environments of the increased stability, among others. More recently, I.I. Abarzhi focuses his research on the processes of heat and mass transfer and on the developments of energy efficient methods and technological equipment for the production of biofuels from forest waste, including the study of crushing in centrifugal plants and the heat exchange by radiation in atmospheric drying plant type “GREENHOUSE”. Chmel Valerii is a senior research of laboratory heat and mass transfer processes and equipment of the HMTHT department, in 1978 defended his dissertation. Research activities are focused on research and study of kinetic characteristics homophase and heterophase media and their influence on heat transfer heat and weight at a normal flame propagation, studying the combustion of solid, liquid and gaseous fuels for their spontaneous, developing new technologies and gasification combustion of fuels and creation on their basis of fuel users devices on solid, liquid, gaseous and alternative fuels. He was awarded the Diploma of the Ukrainian State Corporation “Ukrbudmaterialy” for improving the technology and production of expanded perlite sand. The most significant scientific achievements: – solved the problem of analytical description of the diffusion torch in the system of flat-parallel jets in self-ignition mode and developed a method for calculating its parameters, determined the influence of harmonic pressure fluctuations on the flat flame front and the influence of flame torch and nozzle edges on the boundary layer thickness. On the basis of the developed method of thermochemical treatment of fuels and two-stage process of combustion in the clamped layer and afterburning in the system of oxidant jets in the self-ignition mode, burner devices were created. – established for the two-stage process of burning solid fuel burner unit restrained over layer used in heat generators of various thermal power in the dryer companies: LLC “Yavor-M” (Kalynivka, Vinnytsia region), Ltd. “Noteks” (Sumy), LLC “Oriy” (Berezan) and others. – the results of research on the interaction of perlite with high-temperature gases were put into the development of technology and equipment for the production of expanded perlite sand, which have been implemented in Ukraine, the Russian Federation, Greece and Kazakhstan. – together with CJSC “Experimental Plant of Welding Equipment named after E.O. Paton” on the instructions of the Government “Development of technologies and equipment for environmentally friendly processing of hazardous waste using plasma and other highly efficient energy sources” created a technological scheme and gas generator for recycling garbage into fuel gas. For the period 2015 – 2019 performed, as a manager, 15 business contracts. In 2019 – 6 contracts the total amount of which was 1533736 UAH. Currently, works are underway to modernize the heat generator and drum dryer of mineral fertilizers for Oriy LLC (Berezan). He has 75 publications, including 9 inventions. The results of the works were presented at scientific conferences in Ukraine and Germany, Poland and Russia. Timoshchenko Andrey Vladimirovich is a leading researcher of the laboratory of heat and mass transfer processes and devises of the HMTHT department, in 2007 he defended his candidate dissertation (Ph.D.); in 2006 – Scholar of the Presidium of the National Academy of Sciences of Ukraine; in 2007 – the award for young scientists “Talent, inspiration, work”; in 2009 – the award of the Verkhovna Rada of Ukraine for the Most Talented Youth; in 2019 – International Award at the Third Session of Entrepreneurial Talent Leaders (Shanxi, Shenzhou, China); in 2019 – Certificate of successful completion of an internship in Mechanical Engineering (ACME Information Technology Ltd. Zhejiang, China). Scientific activity is aimed at the study of hydro-gas-dynamic and heat-mass transfer high-temperature transfer processes in the elements of industrial equipment and the development on their basis of energy-efficient processes and devices. Responsible executor in the creation and implementation of seven heat technologies (latest processes, devices, and production lines) in the production of basalt fibers and products based on them. Research activities are aimed at studying the processes of flow and heat and mass transfer of liquid and gaseous media in the elements of heat technology equipment. Design and engineering activities are aimed at developing energy-efficient engineering systems (heat supply, ventilation, aspiration, heating), innovative heat and mass transfer equipment, heat exchangers of recuperative, regenerative, and mixing types, devices for separating and draining condensate of steam, of the heat generators of the convective drying units, gas heating basalt smelting tank furnaces, system modernization of multi-stage technology for the production of staple and continuous basalt fibers and thermal insulation and composite materials based on them. In recent years, developed and implemented, with the definition of the main technical and economic indicators, in terms of long-term controlled operation: – the prototype model of the tank furnace of the recuperative type for basalt smelting brand PPB-1RC; – the prototype model of the tank furnace of the regenerative type for basalt smelting brand PPB-2RG; – experimental-industrial model of the new energy-efficient unit for the production of basalt super thin fiber (BSTF) by duplex technology; – modernized conveyor plant for drying of flat semi-rigid heat-insulating products on the basis of BSTF; – modernized tunnel plant of convective drying of discrete-continuous action; – the prototype model of the new energy-efficient modular unit for the production of basalt continuous fiber (basalt roving); – innovative technological line for the production of fire-resistant composite panels. There are 13 patents and more than 50 scientific publications.