Description of the performed and completed projects

1. Improvement of combustion chambers of fire-tube boilers

The goal of the work: intensification of heat produced, as well as an analysis of the influence of numerical sensitive and constructive parameters on heat transfer in combustion chambers.

Characteristics of work

In the process of execution of the work:

-methods of numerical solution of the equations of energy transfer radiation in symmetrical volumes;

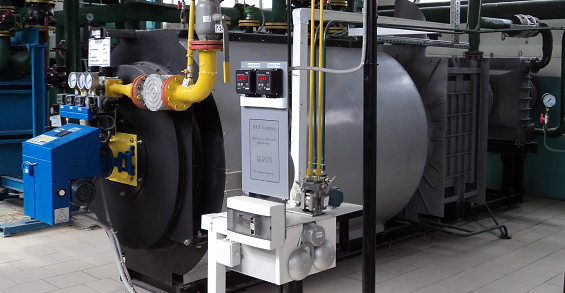

-established experimental stands for “laboratory research of intensification of heat exchange processes in combustion chambers of fire-tube boilers” and “laboratory of fire research technical solutions for modernization of combustion chambers;

|

|

Figure 1. The appearance of the laboratory stands.

-the influence of heat in a volume on torch radiative-convective heat transfer in combustion chambers;

-studied the process of Burnout of fuel in the entirety of the torch, which significantly affects the distribution of the surface density of the resulting radiant flows along a secondary radiator;

-the influence of effective degree of blackness firebox εэф on local and summary result heat flux on surface of heating;

-established that the selectivity of radiation greatly affects the combustion characteristics of local and total heat transfer in combustion chambers;

-the concentration of nitrogen oxides depending on the multiplicity at the recycling of combustion products;

-developed methodology for calculating secondary emitters for fire-tube boilers;

– development of design documentation for introduction in production of secondary emitters for boilers type BK-21, VK-22 and VC-32.

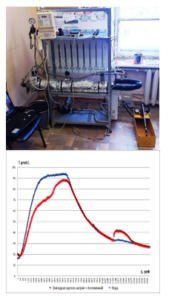

2. Development and application in production of secondary emitters for flue boilers of fire-tube cameras

One possible and feasible ways to increase utilization of fuels in boilers is intensification of heat exchange and, accordingly, heat transfer in combustion chambers. Employees on tidal intensification technology developed by installing secondary emitters that are designed to improve fuel efficiency and reduce the generation of toxic emissions into the atmosphere, resulting in savings of natural gas and reduction of nitrogen oxides in half and with CO five times.

|

|

|

Figure 2. The appearance of secondary emitters.

3. Flue gas heat recovery steam generators based on pipes with incomplete transverse ribbing for ptvm-30 m (40 Mw), CVG-6 MW and KW-4, 65MVt.The goal of the work: development of design and project documentation, methods of calculation and commercializing flue gas heat exchangers based on pipes with incomplete transverse ribbing for ptvm-30 m (40 Mw), CVG-6 MW and KW-4, 65MVt.

Characteristics of work: utilizer uses a portion of the heat of flue gases that are formed during combustion of fuel in the combustion chamber of the boiler for heating water, which increases the efficiency of heat recovery allows to reduce boiler. the production cost of warm energy, reduce harmful gases that are released into the environment and improve the utilization rate Wednesday fuel. Developed by waste heat based on the flat oval ducts pipes with incomplete transverse ribbing provide 1.3-1.5 less aerodynamic drag compared to waste heat, made of round ducting with lateral twist ribbing.

|

|

|

|

Figure 3. The appearance of flue gas heat exchangers.

4. Gas hot water boiler with the thermal power of 1.25 MW with heat boiler flue gas heat

The goal of the work: development and commissioning of gas boilers brand KVMU-1.25 NG.

Characteristics of work: boiler KVMU-1.25 Ng is designed for heating and hot water supply of residential, industrial and administrative facilities in closed systems-supply boiler. modular construction allows you to use each module separately or production design them in modernization of existing and construction of new plants. Universal design of firebox allows to operate the boiler w burners of varying design, powered by natural gas, diesel fuel, waste production and biofuel. In addition to the production of heat energy in boiler electrical energy produced a robot, which is enough to power the engines of the circulating pumps and automation unit through the use of thermoelectric generators.

Figure 4. The appearance of the boiler KVMU-1.25 NG.

Boiler KVMU-1.25 Gn introduced and operated at KP “Harkovteploseti” Kharkov with efficiency up to 98%. Received up to 40% savings of natural gas compared with working on boilers of the old design.

5. Pot of water heating unified CVU-0.5 t

Purpose: for heating and hot water supply of residential, industrial and administrative buildings in closed heating systems.

Advantages: burning different types of solid biofuel; application of the burners according to different principles of action; payback period of 18 months; support for the maximum possible efficiency (not less than 90%); the design allows you to quickly replace the basic elements of the boiler in the operation.

Efficiency: the replacement of the use of natural gas for solid fuels; reduction of emissions of NOx up to 300 mg/m ³ and emissions of CO to the 50 mg/m ³. Patent of Ukraine № 95495

6. Study of heat transfer during movement of Biphasic streams in tubes of condensers for air cooling

The purpose of the work: improving the effectiveness of horizontal-tube condensers in which the steam condensation process occurs inside the tube, by scientifically optimal range of operating parameters of two-phase flow with condensation in the horizontal pipe.

Characteristics of work

Work accomplished: solution of inverse problem of heat transfer process of stationary heat to ensure the realization of the method of thick-walled pipes and based on its definition of local coefficients-around the perimeter of the thin-walled pipes;

-experimental research of heat transfer process steam condensation inside horizontal smooth tubes for stratifications-wave and annular modes currents two-phase steam condensation flow;

-as a result of the analysis of research results corrected known generalized dependencies for calculation of average heat transfer during condensation

7. Two Burner Burning big fraction biofuel

The purpose of the work: the establishment of efficient furnaces that allow you to burn a wide range of waste biomass and low-quality coal.

Characteristics of work:

Fuel combustion in the clamped layer burning occurs at high heat potential mirrors and high gradient speeds an oxidizer. A special takeaway from a pinched layer and combustible gases has ignition temperatures. Therefore, highly efficient combustion process forced almost all types of solid fuel is a two-step process, consisting of the main process of burning in the clamped layer and process gas phase emission and reburying (fuel and Coke particle) self-ignition in the stream mode.

Figure 5. General view of burner pinched layer

Our studies have shown that the process of burning loot layer operates at a temperature greater than 1000 to that lead to Burnout Volatiles and Coke residue. For integral layer of deflagration occurs in the gas phase, ensuring completeness of combustion up to 99%. Managing the process of combustion produced frequency engine blow fan. Burners for combustion of layer a pinched big fraction solid fuel may have planeparallel or axially simetrical of the traffic components.

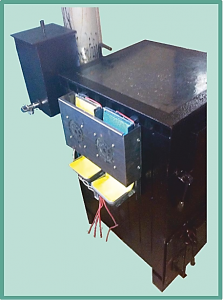

8. Heating-cooking stove «Record», long burning

The purpose of the work: creating the furnace “record” with universal fuel consumption and long its combustion (up to 6:00 with the same fuel tab). The oven “record” can work on any type of fraction solid fuel, namely: wood, brown coal, peat, precast pressed straw, wood chips, briquettes and pellets, as well as grain cereals.

Characteristics of work

For efficient heating of tents, underground fortifications, temporary and suburban buildings, industrial and garage premises up to 220 m3 in developed, researched, tested in laboratories and manufacture multifunctional heating cooker-oven “record”.

This effect managed to achieve using new original projects of the Division to change the technology and kinetics of fractional combustion of solid biofuel by using two or more zones of pyrolysis.

|

|

Figure 6. The appearance of the heating-cooking oven «record»

Further developed and tested design of water and air heat exchangers with thermoelectric modules for obtaining electric energy due to temperature differences, thus allowing for the lighting of premises, as well as the charge mobile phone batteries, radios and other equipment.

Product meets the requirements of DSTU 3075-95 (GOST 9817-95) “household equipment that works on solid fuel. General technical conditions and FIRE a. 01.001-2004 “rules of fire safety of Ukraine”.

9. The thermal network coaxial is pipelines

Purpose: to transport heat away from source of heat energy to the consumer distribution pipelines and a new design of main heating systems

Advantages: no loss of heat to the environment of the feeding pipeline; provided to prevent from mechanical and thermal deformation and output from the system feeding piping.

Efficiency: reduced fuel consumption for heating the coolant in boiler house; provided quality indicators of the coolant when feeding to the consumer; reduced material costs at underground laying trails of thermal network. Patent of Ukraine № 105366

10. A new powerful program of automatic data processing and new automatic electronic hub dimensions

In 2017, the Lab VIEW software platform created by the algorithm and applied computer program of simultaneous measurement of analog signals from sensors, pressure and temperature:

- Developed experimental tools for the short-lived and long-term research on the measurement of thermal effects of high-temperature sorption/desorption of hydrogen in the crystal lattice of a solid body.

- Organized collection, processing and analysis of experimental results.

- Advanced hypothesis and theoretical model on “nature” warmth and opportunities for implementation of exothermic reactions in the studied systems “nickel-hydrogen”.

- The search was conducted and elaboration of mathematical models of processes in macro-, micro-and nanodisperse environments, depending on the dimension of the factions, the density of the backfill (coordination number of boxes of particles of a powder) and gas filler.

- Started development of the fuel cell designs and reactors on the basis of systems hydrogen-metal”.

- When converting electrical energy into heat for the first time obtained the conversion ratio is 1,4

11. Model of the heat accumulator with phase transition

12. «Research Services on conducting the energy expertise of TES (the efficiency of burning natural gas as heating, etc.); instrumental control of technological parameters of work of boilers and heating equipment (temperature modes, equality covering loads, heating and ecological parameters of work, modes of operation, utilization) on objects Novorozdìlska and Novoyavorivsk CHP for 2013-2015 years.

The aim of the work:

- implementation of energy-saving expertise, documentary analysis of the existing condition of cogeneration systems, performing calculations make a fuel and energy resources, determination of actual thermal losses and the cost of fuel and heat when generation, transportation and distribution of thermal energy, energy-saving evaluation system in the operation of systems and development of technical re-equipment, generalization of information, identifying the reasons disparity of actual and normative values of the relevant indicators of the functioning of the heating system, the development of proposals aimed at reducing energy costs.

Description of work:

- defined:-modes power-load boilers, fuel distribution System and water supply;-the actual caloric ability of primary fuel and its conformity to the project;-the suitability of the burning of natural gas established by boiler equipment; the main technical and economic indicators of the equipment in the dynamics of work.

- Was analyzing and:-reconstruction of the equipment during the operation;-technical reports has commissioning tests:-features and balances the heating scheme in part:-holiday heat external consumers and for own needs;-availability of flows fluids between individual units and groups.

- conducted: -the analysis of accounting of spent fuel 2013-2015;-analysis of the method of implementation of the calculation of fuel used on economic and other needs, and also sold a third of consumers;-analysis of fuel testing equipment when you enter it into operation after installation and during the middle and work overs; -analysis of the costs of thermal energy in the network through the insulation of the pipelines, as well as the loss of coolant accident when rains, leaks, unauthorized water theft; -calculation of the actual loss of thermal energy and make a LANE at the generation, transportation and distribution of heat energy; -assessment of energy efficiency energy saving system in the operation of systems; -composite heat balances; -are the real EFFICIENCY of CHP and conditional fuel for production of heat power in 2013-2015 p.

- defined: -causes of unplanned launches boilers, matching the actual costs of fuel, heat and electricity to the firings of their normative values;-cause irrational (inefficient) use of fuel and energy resources and sources of energy losses (overrun) and reducing efficiency.

- proposed:-the results of the evaluation of losses PER use to determine priority directions of energy-saving measures, which are to implement and ensure the economic mechanism of energy conservation: proposals aimed at reducing energy costs.

Economic impact:

- Taking into account the specific recommendations, see the CHP received fuel consumption for electric heat and over normative losses in heating system, conducted an inventory of heating systems and connecting to them, correcting permanent the standard of the heat loss in a thermal networks and priority plans of the training system of heating for heating season 2017-2018 years, the further modernization of equipment of THERMAL POWER PLANT and heating systems

- The total annual economic impact of the implementation of the recommendations of the VPTT NASU ÌTTF is about 3200000.00 UAH per year.

13. Feasibility study: “the desirability and feasibility of conversion of existing boilers TC-35 and De 10/14GM with natural gas on biofuels with the aim of preserving the installed capacity for the production of TPP Akhtyrka electric and thermal energy

The purpose of the work : a study of the current state of the TEC, consideration and use of alternative fuels in the Akhtyrka CHPP to replace natural gas and fuel oil in its fuel and energy balance.

Characteristics of work:

Study of fuel properties of biomass as alternative fuel indicated the desirability and feasibility of conversion of existing boilers de-10/14-250GM and TC-35 type Akhtyrka TPP from natural gas to biofuels with preservation of installed capacity on production of electric and thermal energy.

Conducted the necessary thermal and aerodynamic calculations are balances. economic feasibility of transfer of TPP is defined for incineration of solid biofuels. fuel expenses are substantiated, selected main and auxiliary equipment. Developed conceptual and planning decisions. Proposed an original method of burning biofuel. Identified needs of land necessary for the cultivation of energy wood. Decide what transfer Ahtirka heat power station bring meaningful economic effect over substitution natural gas by biomass. Near this term of recoupment of investment by transfer boilers of heat power station on alternative hard fuel put together one or two month.

14. Programming optimization of heat supply systems Zhashkov Cherkassy region and Mogilev-Podolsk Vinnitsa oblast.

The goal of the work: based on initial data collection and analysis, development of the technical, organizational and economic retooling of heat supply systems of cities aimed at saving energy and fuel resources and reducing their use. This will have a positive impact on reducing production costs and financial sustainability of the enterprises in the coming years.

Characteristics of work: conducted an energy audit of the heat supply system of the city, on the basis of the received data revised scheme, and implemented hydraulic and thermal calculations. Developed activities on energy efficiency were the selection of the preferred and auxiliary equipment. The price has been determined and the payback period of the proposed activities. Recommendations on implementation and modernization of boiler equipment, transmission and distribution networks. A set of fast payback activities performed by the user.

Introduction modernization hydraulic circuits of boiler:

-will provide significant savings in natural gas consumption;

-improve the performance characteristics of boiler equipment;

-increase the service life of boilers;

-improve quality indicators supplied to consumers of thermal energy.

The work is done-received acts implementation. Fuel savings amounted to 15% for 1 Gcal.

Recommendations on application of technical, organizational and economic decisions that is necessary to conduct optimization of heat supply systems of cities.

15. Conduct energy surveys of heat networks of PJSC «Ingok»

The purpose of the work: definition of heat losses in the existing thermal networks, development of measures to reduce the cost of transport, distribution and use of thermal energy utilizes the PJSC “.

Characteristics of work: defined heat losses in existing thermal networks through measurements of heat flow and temperature on thermal enterprise networks.

At the same time:

-designed heat balance of heating networks;

– analyzed the existing heating system and temperature and climatic conditions of the JSC INGULETS MINING “;

-studies of pipelines of the company;

– calculated heat loss regulative;

-thermal testing thermal networks Enterprise;

-specify actual heat loss on the sections of the platform.

Developed activities to reduce the cost of transport, distribution and use of thermal energy JSC ingok.

When this:

-analyzed the possibility of using electric heat for individual buildings of JSC Ingok;

-developed several options to translation of part of consumers on autonomous gas heating;

-analyzed the usefulness of at Automatic tubes sites for thermal energy consumption control;

-developed several options for replacing outdated heating mains isolation;

-approaches to implement the system of commercial and technical accounting heat energy for JSC Ingok.

16. Conducting ecological and thermotechnical tests the influence of additives on the combustion process Shelvin and reduce toxicity of combustion in boilers that run on coal and pellet

The purpose of this paper – study of the influence of consumables catalysts on combustion of charcoal and wood pellets in hot-water boilers of low power.

Characteristics of work: experimental study of the determination of the conditions of the burning charcoal and wood pellets with additive Shevlin in an experimental boiler and studied the speaker and thermal changes and environmental characteristics of the boiler.

|

|

Figure 11. Stoker grate device for burning solid fuels.

Using gas in flue gases monitored changes in oxygen content, nitrogen oxide, carbon monoxide and bit (e) for the boiler, analytical by determined fuel/air ratio (α) and carbon value, efficiency, heat loss from departing gases, dew point.

The studies determined that the addition of coal additives Shelvin at concentrations as low as 1.0 ml to 1.0 liter of water improves boiler efficiency by an average of 1.3%, and 6% furnaces EFFICIENCY, reduced co content in flue gases by 7%, the temperature in the furnace increases, on average, 12.5%.

Adding to wood pellets additives 1.0 ml concentration Shelvin to 1.0 liter of water improves boiler efficiency by an average of 1% and an EFFICIENCY of furnaces-5.5%, reduced co content in flue gases at 16%. The temperature in the furnace increases, on average, at 39.3%.

17. Research on reducing heat losses in centralized heating systems

The purpose of the work is to determine, on the basis of theoretical and experimental research, the reduction of thermal costs during the generation, transport and distribution of thermal energy, the development of technical solutions and new technologies to increase the efficiency of thermal energy equipment and central heating systems by reducing and compensating thermal losses.

Job characteristics:

– an analysis of the current state of operation of thermal energy equipment and heat supply systems was carried out, a thermal energy accumulation scheme was proposed and parameters affecting heat exchange were determined; technical solutions for the utilization of low-potential heat were developed, experimental studies of thermophysical parameters affecting heat consumption, harmful emissions and total fuel consumption were carried out;

– on the basis of the obtained experimental and calculation data, technical means of increasing the efficiency of the heating system and reducing heat costs during the generation and transport of thermal energy have been developed;

– a system for transporting the heat carrier through coaxial pipes was developed, research was carried out on the conversion of electrical energy into thermal energy using exothermic reactions that occur in the process of oxidation of transition metals with alkali during hydration with hydrogen, criteria for the use of coaxial pipes for the construction of new and modernization of heating networks were formulated.

– manufacturing, installation and commissioning of two experimental samples (mock-ups) of the heat accumulator were carried out. When converting electrical energy into thermal energy, a conversion factor of 1.4 was obtained for the first time.

– received an act of introduction into serial production of a line of water heating boilers that work on biological fuel at the TDV “BZKU” enterprise, at the same enterprise the experimental “Stand No. 4 VPTT for the study of combustion processes and heat exchange during solid fuel combustion” was created and put into operation . The use of mobile heat accumulators to create a fundamentally new discrete system of heat and cold supply is theoretically substantiated.

– for the first time in the world, the author’s original system of multi-criteria analysis and strategic decision-making was tested. It was tested during the performance of works: conducting thermal and ecological tests of liquid biofuel and developing methods of burning it; conducting experimental heat-ecological tests and comparative calculations of 7 water-heating boilers

– implementation of scientifically based energy-saving recommendations to reduce heat consumption in boiler equipment and heat networks, development of new technologies, devices and equipment for economical and reliable operation of heat networks is expected.

18. Development of a system of storage and mobile transportation of thermal energy

The purpose of the work is to develop a system of storage and mobile transportation of thermal energy, working design documentation, production of a prototype of a container-type mobile heat accumulator (MTA) and other elements of the system.

|

| Fig. 10. Mobile thermal energy storage (M-TES) |

|

|

| Fig. 11. Individual heating point |

|

|

|

| Fig. 14. Transportation of a mobile thermal energy storage (M-TES) |

Job characteristics:

– for the first time in the world, the basics of the concept of a new generation discrete heating system, which is energy efficient and environmentally safe, have been developed. A fundamentally new design of the thermal energy storage and transportation system was developed, which involves the use of non-productive thermal costs of enterprises, waste of various origins, for example, agricultural enterprises, local industries, etc.;

– calculations of the productivity of the mobile thermal energy storage (M-TES) in terms of heat and cold depending on the capacity of the heat storage materials (HST);

– calculations of the stress-strain state on the strength of the storage tank during transportation were carried out;

– a set of working design documentation was developed for the production of a test sample of container-type M-TES;

– a list of structural materials for a mobile heat accumulator, results of assessment of the effect of chemical corrosion of HST on structural elements are given;

– the optimal composition of a mixture of chemical substances for the accumulation of heat at negative temperatures of the outside air is described; the dependence of the mass and volume of the HST on the density of stored energy, the efficiency of the accumulation process; conditions of application of crystallization initiators and special thickeners, protective chemical or galvanic coatings;

– complex experimental studies and scientific research works aimed at finding components that will be used as a heat-accumulating substance, based on which water-soluble polymers were chosen for the creation of pseudo-plastic binary water systems, which significantly increase the specific heat capacity and heat-accumulating capacity of water coolants, were carried out.

- Demchenko V.Konyk А., Dekusha О. Thermal Energy Storage Systems in the District Heating Systems/ Book: Systems, Decision and Control in Energy V. p. 371-384 DOI : 10.1007/978-3-031-35088-7 eBook ISBN 978-3-031-35088-7; Print ISBN 978-3-031-35087-0 (Scopus, Springer )

- Demchenko V., Konyk А., Dekusha H. Determination of components for heat storage materia. IOP Conference Series: Earth and Environmental Science , Volume 1254, 4th International Conference on Sustainable Futures: Environmental, Technology, Social and Economic Matters (ICSF-2023) 22/05/2023 – 26/05/2023 Кривий Ріг, Україна DOI 10.1088/1755-1315/1254/1/012033 (Scopus)

- Ivanitsky G.K.,Konyk А.V., Stepaniuk A.R., Demchenko V.G. simulation of heat exchange processes in the “thermal core” filled with heat accumulation material. Energy Technologies & Resource Saving (2023) р.52-70 https://doi.org/10.33070/etars.3.2023.05 (Scopus)

- Smernytskyi D.V. Multifunctional transportable heat accumulator of the capacitive type. Relevance and expediency of use in units of the Ministry of Internal Affairs /Smernytskyi D.V., Demchenko V.G., Konyk A.V., Ryabiy S.M., Marchenko O.G., Zhvanko Yu.P.// Modern special equipment, 2023. No. 1. – P. 153-160. ISSN 2411-3816

- Demchenko, V., Kovtun, S., Nazarenko, O. and Nazarenko, A., Experience of using thermal accumulators in blackout conditions, System Research in Energy, 2023. 4 (75), https://systemre.org/index.php /journal/article/view/812 p. 17-31.

19. Research of thermal environmental characteristics of water boiler kV-BT 1.6 capacity of 1.6 Mw running on solid fuel address: District Hospital in Lutsk, Rivne region.

The results of the test were provided recommendations for the improvement of boiler equipment, which were used by the company PE “heat energy” when mass production of solid fuel boilers. Also, taking into account the received recommendations, the current modernization of boiler equipment, which carried out maintenance service. Taking into account the recommendations of the NATIONAL ACADEMY of SCIENCES ÌTTF VPTT allows you to lengthen the lifetime of boiler equipment, reduces thermal and mechanical load on the units fixing the dimogarnih sections of the pipelines and, most importantly, reduces fuel consumption by producing 1 Mw thermal energy at about 10% compared with the base construction. The overall economic effect, resulting in 2016, from implementation of the recommendations of the VPTT ÌTTF, is about 800000.00 UAH. VAT.

20. Calculation of norms expenses solid pellet fuel from waste wood and straw at the different modes work tverdopalivnoï boiler for planning needs of enterprises in peletnomu fuel and control its expenditure, accounting, the introduction of a regime of savings and the rational use of fuel. ?

Indicators carried out measurements and data obtained by the specialists of the Department was developed «methodology of calculations of planned fuel consumption standards, which are based on the evaluation of the equipment in specific conditions, comparative analysis of the fuel consumption and sets regulatory deviation of individual regulations cost of passport data of fuel expenditures. In the boiler room of the International Airport “Kiev” implementation methods of calculations of planned fuel consumption standards “for the heating season 2015-2016, and the period from October through January 2016 2017 year year yielded savings of approximately 30 tons of pellets from sunflower in monetary equivalent is 39000 UAH. VAT and 24 tones of wood pellets valued 68400 UAH. VAT. The total savings is 107400 UAH. VAT.